Inhaltszusammenfassung für Milnor StaphGuard

- Seite 1 Published Manual Number/ECN: MQCWSO01U1/2013386A • Publishing System: TPAS2 • Access date: 09/20/2013 • Document ECNs: Latest 42044 & 60044SP2/SP3 72044SP2 PELLERIN MILNOR CORPORATION POST OFFICE BOX 400, KENNER, LOUISIANA 70063-0400, U.S.A.

- Seite 3 Guide de l’opérateur—StaphGuard® Laveuse-essoreuse avec contrôleur Mark VI MQCWSO01FR/20070515 4. Español Guía del operario—StaphGuard® Lavadora extractora MarkVI MQCWSO01ES/20070515 5. Türk Kullanc rehberi—StaphGuard® Mark VI Kontroller ile Ykama Skma Makineleri MQCWSO01TR/20070515 6. Polski Instrukcja Uytkownika—StaphGuard® Pralka-wirówka ze sterownikiem Mark VI MQCWSO01PL/20070515 7. Deutsch Betriebshandbuch—StaphGuard®...

- Seite 5 English...

- Seite 7 • Access Date: 20070515 • Custom: n/a • Applicability: CWS • Language Code: ENG01, Purpose: publication, Format: 1colA Operator Guide— ® StaphGuard Washer- extractor with Mark VI Controller PELLERIN MILNOR CORPORATION POST OFFICE BOX 400, KENNER, LOUISIANA 70063 - 0400, U.S.A.

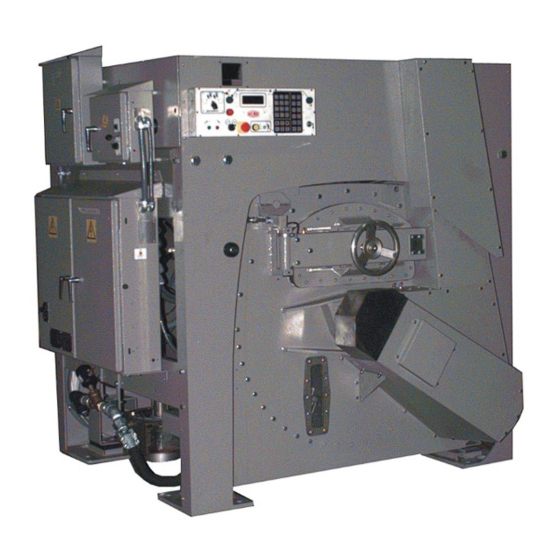

- Seite 8 Applicable Milnor products by model number: ® 42044SP2 42044SP3 60044SP2 60044SP3 72044SP2...

-

Seite 9: Inhaltsverzeichnis

(Document BICWCO03) 2.1.1. Start Here for Safety 2.1.2. Check Switch Settings ® 2.1.3. How do I Load a StaphGuard Machine? 2.1.4. How do I Select a Formula? Figure 9: Selecting a Local or Remote Formula 2.1.4.1. Selecting a Local Formula... - Seite 10 2.1.7.2. For End Code 3 (Tumbling) Chapter 3. Signals and Errors 3.1. Operator Intervention (Document BICWCT04) 3.1.1. Error with Operator Signal Figure 16: Typical Error with Operator Signal 3.1.2. Operator Signal for a Chemical Figure 17: Chemical Injection View on Run Display PELLERIN MILNOR CORPORATION...

-

Seite 11: Chapter 1. Controls

The microprocessor box in the upper rear corner of the machine left side panel (see Figure contains a DIN-type connection for serial communications. Use this connection, labelled as shown in Figure 2, with a serial data transfer device to save or restore machine programming and configuration memory. PELLERIN MILNOR CORPORATION... -

Seite 12: What Are The Operating Controls

Door unlock button Jog/Autospot selector switch Control on clean side indicator Control on soil side indicator Master switch for power Operator signal and signal cancel button Liquid crystal graphic display Run/Program keyswitch Keypad Start button Stop button PELLERIN MILNOR CORPORATION... - Seite 13 • When you reset this button, you have the option of cancelling or resuming the interrupted formula. The formula resumes where it was interrupted or at the beginning of the previous bath step, depending on the operation in progress when the emergency stop button was pressed. PELLERIN MILNOR CORPORATION...

-

Seite 14: What Does This Switch Do

), only formulas present in the machine are available. Figure 6: Mildata/Local Selector switch Manual supply flush button (Figure 7)—On machines equipped with an optional flushing supply injector, press this button to spray water into the supply injector to flush any remaining PELLERIN MILNOR CORPORATION... - Seite 15 8)—Some divided-cylinder machines are equipped with the Autospot feature to aid in loading and unloading. This optional feature optimally positions the basket for access to the selected pocket. Figure 8: Autospot selector switch — End of BICWCO02 — PELLERIN MILNOR CORPORATION...

-

Seite 16: Chapter 2. Normal Operation

Check Switch Settings 2.1.2. Display or Action Explanation Check that the run/program keyswitch is at All emergency stop buttons must be unlatched and in the ready position to allow machine operation. Check that the master switch is at PELLERIN MILNOR CORPORATION... -

Seite 17: How Do I Load A Staphguard

Chapter 2. Normal Operation ® How do I Load a StaphGuard Machine? 2.1.3. Display or Action Explanation Open the outer door. Select a pocket to load. Align the selected pocket with the outer door. Open the inner door of the first pocket to load. - Seite 18 200 units when prompted, the machine will use twice as much water as if you entered 100 weight units. This option can save a significant amount of water if you enter accurate weights for each load. PELLERIN MILNOR CORPORATION...

-

Seite 19: Selecting A Mildata Formula

12) to choose the best formula for the goods in the machine. Note 1: You can store up to 1000 different wash formulas on the Mildata computer. All of these formulas are available to all washer-extractors that are part of the Mildata network and have compatible hardware. PELLERIN MILNOR CORPORATION... -

Seite 20: Entering Mildata Batch Codes

Figure 13 2.1.4.3. to prompt you for the batch data fields selected in machine configuration (see the related section in document BICWCC01). The data you enter is sent to the Mildata computer for accounting and report generation. PELLERIN MILNOR CORPORATION... -

Seite 21: Start The Selected Formula

1. You've loaded the machine at or near its rated weight capacity. 2. You've selected a formula that's appropriate for the goods in the machine. 3. You've entered any batch data the machine controller requires for metered water or Mildata reporting. PELLERIN MILNOR CORPORATION... -

Seite 22: What Does The Run Display Tell Me

—The top line of the display always shows the number 2.1.6.1. and name of the current formula and step. The formula number appears in the upper left corner of the display, following the letter “F.”The formula name follows the number. PELLERIN MILNOR CORPORATION... -

Seite 23: Basket Rotation

The graphic bath level indicator shows the percentage of the desired level that's achieved. The vertical indicator bar is solid blue when the programmed level is achieved, and solid white when there is no water in the machine. PELLERIN MILNOR CORPORATION... -

Seite 24: Formula Steps And Chemical Injection

If you use any of these buttons to stop a formula with end code 3 (see Section 2.1.7.2), the formula is terminated and cannot be resumed. Open the door for unloading. PELLERIN MILNOR CORPORATION... -

Seite 25: For End Code 3 (Tumbling)

Open the door for unloading. Remove any desired portion of the load. Close the door. Resumes the tumbling action without the operator signal. Tumbling continues for another two minutes, or until you press — End of BICWCO03 — PELLERIN MILNOR CORPORATION... -

Seite 26: Chapter 3. Signals And Errors

These errors usually disable the three-wire circuit, and include a tripped vibration switch or a malfunction of the inverter that controls the motor. Figure 16 shows how a vibration switch error appears on the display. Figure 16: Typical Error with Operator Signal PELLERIN MILNOR CORPORATION... -

Seite 27: Operator Signal For A Chemical

The display changes to show you which chemical to add, but the injection time counter runs only after you cancel the operator signal. PELLERIN MILNOR CORPORATION... - Seite 28 Chapter 3. Signals and Errors Figure 17: Chemical Injection View on Run Display Display or Action Explanation After you've added the chemical, cancels the operator signal and starts the injection time counter. — End of BICWCT04 — PELLERIN MILNOR CORPORATION...

- Seite 29 eský...

- Seite 31 Mark VI Controller] POZOR: The information contained in this manual has been provided by Pellerin Milnor Corporation in the English version only. Milnor has tried to obtain a quality translation, but makes no claims, promises, or guarantees about the accuracy, completeness, or adequacy of the information contained in the non-English version.

- Seite 32 Aplikovatelné Milnor Produkty podle čísla modelu: [Applicable ® Milnor products by model number:] ® 42044SP2 42044SP3 60044SP2 60044SP3 72044SP2...

- Seite 33 2.1. Pracovní instrukce pro obslužný personál (Dokument BICWCO03) 2.1.1. Zde startuj kvůli bezpečnosti 2.1.2. Nastavení kontrolního spínače ® 2.1.3. Jak mohu naložit StaphGuard stroj? 2.1.4. Jak mám zvolit program? Obrázek 9: Volí místní nebo externí programy [Selecting a Local or Remote Formula] 2.1.4.1.

- Seite 34 Obrázek 16: Typická chyba v souvislosti se signálem operátora [Typical Error with Operator Signal] 3.1.2. Signál operátora pro chemikálie (prací prostředky) Obrázek 17: Pohled na vstřik pracích prostředků na běžícím displeji [Chemical Injection View on Run Display] PELLERIN MILNOR CORPORATION...

- Seite 35 (Document BICWCO03) 2.1.1. Start Here for Safety 2.1.2. Check Switch Settings ® 2.1.3. How do I Load a StaphGuard Machine? 2.1.4. How do I Select a Formula? Figure 9: Volí místní nebo externí programy [Selecting a Local or Remote Formula] 2.1.4.1.

- Seite 36 3.1.1. Error with Operator Signal Figure 16: Typická chyba v souvislosti se signálem operátora [Typical Error with Operator Signal] 3.1.2. Operator Signal for a Chemical Figure 17: Pohled na vstřik pracích prostředků na běžícím displeji [Chemical Injection View on Run Display] PELLERIN MILNOR CORPORATION...

-

Seite 37: Chapter 1. Controls

(Obrázek are located on the front control panel (Figure Přídavné ovladače a spojení jsou umístěny 1). Additional controls and connections are kdekoli na stroji jak zde popsáno. located elsewhere on the machine, as described here. PELLERIN MILNOR CORPORATION... -

Seite 38: Where Do I Connect The Data Storage Device

řadový transfer dat k uložení nebo obnově data transfer device to save or restore programovací a konfigurační paměti stroje. machine programming and configuration memory. Obrázek [Figure] 2: Řadové spoje pro transfer dat [Serial Connection for Data Transfer] PELLERIN MILNOR CORPORATION... -

Seite 39: What Are The Operating Controls

Signál pro operátora a Signál zrušit [Operator signal and signal cancel button] Grafický displej z tekutých krystalů [Liquid crystal graphic display] Přepínač Běh/Program [Run/Program keyswitch] klávesnice [Keypad] Start tlačítko [Start button] Stop tlačítko [Stop button] PELLERIN MILNOR CORPORATION... - Seite 40 Oznámení 1 : Stiskni ihned Nouzový stop Notice 1 : Press the emergency stop tlačítko při jakékoliv nouzové situaci. To vyřadí button immediately in any emergency 3-fázový obvod, který zastaví všechny operace situation. This disables the 3-wire circuit, PELLERIN MILNOR CORPORATION...

- Seite 41 Each button may perform more than one základě běžícího stavu stroje. Některá function, based on the current machine tlačítka jsou také používána v kombinaci pro status. Some buttons are also used in PELLERIN MILNOR CORPORATION...

-

Seite 42: What Does This Switch Do

), only formulas present in the machine are available. Obrázek [Figure] 6: Mildata/místní volící spínač [Mildata/Local Selector switch] Tlačítko ručního napouštění (Obrázek 7)— Manual supply flush button (Figure 7)— Na strojích vybavených volitelným On machines equipped with an optional PELLERIN MILNOR CORPORATION... - Seite 43 This optional feature optimálně polohuje koš kvůli přístupu na optimally positions the basket for access volitelný žok. to the selected pocket. Obrázek [Figure] 8: Volící spínač Autospotu [Autospot selector switch] — Konec BICWCO02 — — End of BICWCO02 — PELLERIN MILNOR CORPORATION...

-

Seite 44: Chapter 2. Normal Operation

Musíš jasně porozumět nebezpečím a vědět jak jim předcházet. • Do not service the machine unless qualified and authorized. You must clearly understand the hazards and how to avoid them. PELLERIN MILNOR CORPORATION... -

Seite 45: Check Switch Settings

Zkontroluj, že hlavní spínač je v Check that the master switch is at ® ® Jak mohu naložit StaphGuard How do I Load a StaphGuard 2.1.3. stroj? Machine? Displej nebo akce Vysvětlení Explanation [Display or Action] Otevři Venkovní... -

Seite 46: Selecting A Local Formula

(Obrázek 10) k vybrání stored in local memory on the machine. Use správného programu pro zboží ve stroji. the Select Local Formula screen (Figure to choose the correct formula for the goods in the machine. PELLERIN MILNOR CORPORATION... - Seite 47 PELLERIN MILNOR CORPORATION...

- Seite 48 100 weight units. This option can váhy každého nákladu. save a significant amount of water if you enter accurate weights for each load. PELLERIN MILNOR CORPORATION...

-

Seite 49: Selecting A Mildata Formula

Mildata computer. All of these programy jsou použitelné pro všechny pračky co jsou formulas are available to all washer-extractors částí Mildata sítě a jsou kompatibilní. that are part of the Mildata network and have compatible hardware. PELLERIN MILNOR CORPORATION... -

Seite 50: Entering Mildata Batch Codes

BICWCC01). Data co jsi the related section in document zapsal jsou poslána do Mildata počítače pro BICWCC01). The data you enter is sent to spočtení a nahlášení. the Mildata computer for accounting and report generation. PELLERIN MILNOR CORPORATION... - Seite 51 číslo cesty k několika účtům. Číslo common to several accounts. A lot lotu může mít až 10 číslic. number can be up to 10 digits long. PELLERIN MILNOR CORPORATION...

-

Seite 52: Start The Selected Formula

While the machine is running the formula zvolil, displej ukazuje to samé co je v Obrázek you selected, the display appears similar to 14. Zde zobrazená informace je vysvětlena dole. the one shown in Figure 14. The information shown here is explained below. PELLERIN MILNOR CORPORATION... -

Seite 53: Formula And Step Information

The formula number appears in the symbolem “F.” symbol Jméno programu a to upper left corner of the display, following the následně za číslem. letter “F.”The formula name follows the number. PELLERIN MILNOR CORPORATION... - Seite 54 Prázdný (nepracující?) Volný doběh 1-způsob praní Čekám na vypouštění 2-způsob praní Čekám na naložení Namáčení Zpoždění pohonu ? Přípravné+Konečné ždímání Vypouštění do kanalizace Meziždímání Vypouštění k dalšímu použití Konečné ždímání Časovač zastaven Dvojité ždímání Prosím počkejte xx vteřin PELLERIN MILNOR CORPORATION...

-

Seite 55: Basket Rotation

The arrow is not visible when level is achieved, or during extract steps. Kontrolér ukazuje Údaje o teplotě vody a The controller displays bath temperature and hladině údaje teploty a grafických indikátorů level data between the temperature and level PELLERIN MILNOR CORPORATION... -

Seite 56: Formula Steps And Chemical Injection

(see Figure 15). té uvedené dole pro vyložení zboží. Use a procedure similar to the one outlined below to unload the goods. Obrázek [Figure] 15: Typická zpráva když program skončí [Typical Message when Formula Ends] PELLERIN MILNOR CORPORATION... - Seite 57 (viz. Sekce 2.1.7.2), se program formula with end code 3 (see ukončí a nemůže se v něm Section 2.1.7.2), the formula pokračovat. is terminated and cannot be resumed. Otevři dveře pro vykládku. Open the door for unloading. PELLERIN MILNOR CORPORATION...

-

Seite 58: For End Code 3 (Tumbling)

Resumes the tumbling action operátora. Máchání pokračuje without the operator signal. po další dvě minuty, nebo než Tumbling continues for zmáčkneš another two minutes, or until you press — Konec BICWCO03 — — End of BICWCO03 — PELLERIN MILNOR CORPORATION... -

Seite 59: Chapter 3. Signals And Errors

řídí motor. Obrázek 16 se objeví vibration switch or a malfunction of the když je displeji chyba vibračního spínače. inverter that controls the motor. Figure 16 shows how a vibration switch error appears on the display. PELLERIN MILNOR CORPORATION... -

Seite 60: Operator Signal For A Chemical

17) hlásí to to add chemicals manually. The display samé v jiném případě, ale signál operátora zazní (Figure 17) appears the same in either case, jen je –li naprogramován. but the operator signal sounds only if the PELLERIN MILNOR CORPORATION... - Seite 61 Potom co jsi přidal chemikálii, After you've added the chemical, Zruší signál operátora a cancels the operator signal nastartuje čítač času and starts the injection time vstřikování. counter. — Konec BICWCT04 — — End of BICWCT04 — PELLERIN MILNOR CORPORATION...

- Seite 63 Français...

- Seite 65 ATTENTION: Les informations contenues dans ce manuel ont été fournies par Pellerin Milnor Corporation dans le version anglaise uniquement. Milnor a souhaité obtenir une traduction de qualité, mais ne peut alléguer, ni promettre, ni garantir l’exactitude, l’intégralité ou la qualité des informations contenues dans la version non-anglaise.

- Seite 66 Produits applicables de Milnor ® par numéro de type: [Applicable Milnor products by model number:] ® 42044SP2 42044SP3 60044SP2 60044SP3 72044SP2...

- Seite 67 2.1. Instructions pour le personnel de l’usine (Document BICWCO03) 2.1.1. Commencez ici par sécurité 2.1.2. Contrôlez les positions des commutateurs ® 2.1.3. Comment charger une machine StaphGuard 2.1.4. Comment sélectionner une formule? Illustration 9: Sélection d’une formule locale ou distante 2.1.4.1. Sélection d’une formule locale Illustration 10: Sélectionner une formule...

- Seite 68 3.1. Intervention de l’opérateur (Document BICWCT04) 3.1.1. Erreur avec signal opérateur Illustration 16: Erreur typique avec signal opérateur 3.1.2. Signal opérateur pour un produit chimique Illustration 17: Injection des produits chimiques : Ecran de visualisation du déroulement du programme PELLERIN MILNOR CORPORATION...

- Seite 69 (Document BICWCO03) 2.1.1. Start Here for Safety 2.1.2. Check Switch Settings ® 2.1.3. How do I Load a StaphGuard Machine? 2.1.4. How do I Select a Formula? Figure 9: Selecting a Local or Remote Formula 2.1.4.1. Selecting a Local Formula...

-

Seite 70: 3.1.2. Operator Signal For A Chemical

2.1.7.2. For End Code 3 (Tumbling) Chapter 3. Signals and Errors 3.1. Operator Intervention (Document BICWCT04) 3.1.1. Error with Operator Signal Figure 16: Typical Error with Operator Signal 3.1.2. Operator Signal for a Chemical Figure 17: Chemical Injection View on Run Display PELLERIN MILNOR CORPORATION... -

Seite 71: Chapitre 1. Contrôles

(Figure avant (). Les autres contrôles et connexions se 1). Additional controls and connections are trouvent ailleurs sur la machine, comme cela est located elsewhere on the machine, as écrit ici. described here. PELLERIN MILNOR CORPORATION... -

Seite 72: Where Do I Connect The Data Storage Device

Illustration 2, avec un data transfer device to save or restore appareil sériel de transfert de données pour machine programming and configuration enregistrer ou restaurer la programmation de la memory. achine et la mémoire de configuration. PELLERIN MILNOR CORPORATION... -

Seite 73: What Are The Operating Controls

The primary operating controls are required nécessaires pour faire démarrer et arrêter la to start and stop the machine, select wash machine, sélectionner les formules de lavage et formulas, and monitor machine operation. ontrôler le fonctionnement de la machine. PELLERIN MILNOR CORPORATION... - Seite 74 [Master switch for power] boutons signal opérateur et signal annulation [Operator signal and signal cancel button] Ecran graphique à cristaux liquides [Liquid crystal graphic display] Interrupteur Démarrage/Programme [Run/Program keyswitch] Clavier [Keypad] Démarrage bouton [Start button] Arrêt bouton [Stop button] PELLERIN MILNOR CORPORATION...

- Seite 75 à la machine de fonctionner. Attention 1 : Appuyez immédiatement sur le Notice 1 : Press the emergency stop button bouton arrêt d’urgence dans toutes les situations immediately in any emergency situation. PELLERIN MILNOR CORPORATION...

- Seite 76 Le clavier comporte trois zones : des touches system. The keypad is divided into three alphanumériques, des touches générales et areas: alphanumeric buttons, general des touches spécifiques à une fonction. buttons, and function-specific buttons. PELLERIN MILNOR CORPORATION...

-

Seite 77: What Does This Switch Do

Mildata computer. When set to the Local l'ordinateur Mildata. Lorsque cet interrupteur position ( ), only formulas present in est sur Local ( ), seules les formules the machine are available. présentes dans la machine sont disponibles. PELLERIN MILNOR CORPORATION... - Seite 78 Autospot feature to aid in loading chargement et au déchargement. Cette and unloading. This optional feature fonctionnalité optionnelle permet le optimally positions the basket for access positionnement optimal du panier pour to the selected pocket. l’accès à la poche sélectionnée. PELLERIN MILNOR CORPORATION...

- Seite 79 Chapitre 1. Contrôles Illustration [Figure] 8: Sélecteur Autospot [Autospot selector switch] — Fin BICWCO02 — — End of BICWCO02 — PELLERIN MILNOR CORPORATION...

-

Seite 80: Chapitre 2. Fonctionnement Normal

• Do not service the machine unless d'urgence pour couper le courant de la qualified and authorized. You must machine. clearly understand the hazards and • La maintenance doit être exclusivement how to avoid them. assurée par des techniciens qualifiés et PELLERIN MILNOR CORPORATION... -

Seite 81: Check Switch Settings

être en position ready position to allow Prêt pour permettre le machine operation. fonctionnement de la machine. Assurez-vous que l’interrupteur Check that the master switch principal est sur is at PELLERIN MILNOR CORPORATION... -

Seite 82: Comment Charger Une Machine Staphguard

Chapitre 2. Fonctionnement normal ® Comment charger une machine How do I Load a StaphGuard 2.1.3. ® taphGuard Machine? Affichage ou action Explication Explanation [Display or Action] Ouvre la porte extérieur. Open the outer door. Sélectionnez une poche à Select a pocket to load. -

Seite 83: Sélection D'une Formule Locale

Utilisez l’écran the Select Local Formula screen (Figure Sélectionner une formule locale (Illustration to choose the correct formula for the goods in pour choisir la bonne formule pour les articles se the machine. rouvant dans la machine. PELLERIN MILNOR CORPORATION... - Seite 84 PELLERIN MILNOR CORPORATION...

- Seite 85 100 weight units. This option can Cette option permet de réaliser une économie save a significant amount of water if you d’eau considérable, pour autant que vous enter accurate weights for each load. introduisiez le poids correct de chaque charge. PELLERIN MILNOR CORPORATION...

-

Seite 86: Selecting A Mildata Formula

Mildata. Toutes ces formules seront formulas are available to all washer-extractors disponibles pour toutes les laveuses-essoreuses that are part of the Mildata network and have faisant partie du réseau Mildata et disposant de compatible hardware. matériel compatible. PELLERIN MILNOR CORPORATION... - Seite 87 Après avoir récupéré et vérifié la formule, le After you've retrieved and verified the contrôleur Mark VI vous demande un Données formula, the Mark VI controller prompts for e la charge de linge configuré. any configured batch data. PELLERIN MILNOR CORPORATION...

-

Seite 88: Introduction Codes De La Charge De Linge Mildata

Le numéro de l’employé peut batch. The employee number may be up comporter jusqu'à 5 chiffres. to five digits long. Pièces—nombre de pièces dans la machines. Pieces—the number of pieces in the PELLERIN MILNOR CORPORATION... -

Seite 89: Start The Selected Formula

été programmé pour une injection injection (see Supplement himique (voir Supplément PELLERIN MILNOR CORPORATION... -

Seite 90: Quelle Est La Signification De L'affichage De L'écran Démarrage

à celui you selected, the display appears similar to présenté sous Illustration 14. Les informations the one shown in Figure 14. The information présentées dans cet affichage sont explicitées ci- shown here is explained below. essous. PELLERIN MILNOR CORPORATION... - Seite 91 Indicateur pour la vapeur optionnelle et les valves de refroidissement [Indicator for optional steam and cooldown valves] Indicateur graphique de la température du bain [Graphic bath temperature indicator] Température du bain et données du niveau [Bath temperature and level data] PELLERIN MILNOR CORPORATION...

-

Seite 92: Informations Relatives À La Formule Et À L'étape

Some of the possible machine states are la machine figurent dans Tableau 1. Le cas listed in Table 1. Error messages appear échéant, les messages d’erreur apparaissent immediately below the machine status immédiatement sous le message d'état de la message when required. achine. PELLERIN MILNOR CORPORATION... -

Seite 93: Basket Rotation

Le graphique Indicateur du niveau du bain The graphic bath level indicator shows the indique le pourcentage du niveau désiré qui est percentage of the desired level that's atteint. La barre verticale d’indication est bleu achieved. The vertical indicator bar is solid PELLERIN MILNOR CORPORATION... -

Seite 94: Etapes De La Formule Et Injection Chimique

15). Procédez comme indiqué ci- Use a procedure similar to the one outlined essous pour décharger les articles. below to unload the goods. Illustration [Figure] 15: Message typique affiché à la fin de la formule [Typical Message when Formula Ends] PELLERIN MILNOR CORPORATION... -

Seite 95: For Any End Code

3 (see fin du code 3 (voir Section Section 2.1.7.2), the formula 2.1.7.2), la formule est clôturée is terminated and cannot be et ne peut reprendre. resumed. Ouvre la porte pour le Open the door for unloading. déchargement. PELLERIN MILNOR CORPORATION... -

Seite 96: Pour Terminer Le Code 3 (Séchage)

Resumes the tumbling action opérateur. Le séchage continue without the operator signal. pendant deux minutes, ou Tumbling continues for jusqu’à ce que vous appuyiez another two minutes, or until you press — Fin BICWCO03 — — End of BICWCO03 — PELLERIN MILNOR CORPORATION... -

Seite 97: Chapitre 3. Signaux Et Erreurs

Figure 16 Illustration 16 indique comment une panne du shows how a vibration switch error appears électeur de vibration est affichée à l'écran. on the display. PELLERIN MILNOR CORPORATION... -

Seite 98: Operator Signal For A Chemical

Cette machine peut contrôler un système de This machine can control an automatic pompe à produits chimiques automatique, ou chemical pump system, or it can signal you vous signaler d’ajouter les produits chimiques to add chemicals manually. The display PELLERIN MILNOR CORPORATION... - Seite 99 Après avoir ajouté le produit chimique, After you've added the chemical, annulez le signal opérateur et cancels the operator signal lancez la minuterie d'injection. and starts the injection time counter. — Fin BICWCT04 — — End of BICWCT04 — PELLERIN MILNOR CORPORATION...

- Seite 101 Español...

- Seite 103 Mark VI Controller] PRECAUCIÓN: La Corporación Pellerin Milnor proporcionó la información contenida en este manual, en la Versión en inglés solamente. Milnor realizó su mejor esfuerzo para ofrecer una traducción de calidad, pero no declara, promete o garantiza la exactitud, integridad o adecuación de la información contenida en la versión no escrita en inglés.

- Seite 104 Aplicable Milnor ® productos por número de modelo: [Applicable Milnor products by model number:] ® 42044SP2 42044SP3 60044SP2 60044SP3 72044SP2...

- Seite 105 2.1.1. Comience aquí para no tener accidentes 2.1.2. Revise la posición de los interruptores ® 2.1.3. ¿Cómo yo cargo una máquina StaphGuard 2.1.4. ¿Cómo yo selecciono una fórmula? Figura 9: Seleccionando una fórmula local o una remota [Selecting a Local or Remote Formula] 2.1.4.1.

- Seite 106 [Typical Error with Operator Signal] 3.1.2. Señal del operador para inyectar productos químicos Figura 17: Vista de la inyección del producto químico en la pantalla de correr [Chemical Injection View on Run Display] PELLERIN MILNOR CORPORATION...

- Seite 107 (Document BICWCO03) 2.1.1. Start Here for Safety 2.1.2. Check Switch Settings ® 2.1.3. How do I Load a StaphGuard Machine? 2.1.4. How do I Select a Formula? Figure 9: Seleccionando una fórmula local o una remota [Selecting a Local or Remote Formula] 2.1.4.1.

- Seite 108 Figure 16: Señal para el operador cuando ocurre un error típico [Typical Error with Operator Signal] 3.1.2. Operator Signal for a Chemical Figure 17: Vista de la inyección del producto químico en la pantalla de correr [Chemical Injection View on Run Display] PELLERIN MILNOR CORPORATION...

-

Seite 109: Controls On Mark Vi Non-Tilting Washer-Extractors

(Figura 1). Additional controls and connections are 1). Los controles adicionales y sus conexiones located elsewhere on the machine, as están situados en otra parte de la máquina, en el described here. lugar que aquí se describe. PELLERIN MILNOR CORPORATION... -

Seite 110: Where Do I Connect The Data Storage Device

Figura 2, para conectar el dispositivo data transfer device to save or restore que permita transferir información. En un futuro machine programming and configuration esta información pudiera ser necesaria para memory. reponer la programación y configuración. PELLERIN MILNOR CORPORATION... -

Seite 111: What Are The Operating Controls

The primary operating controls are required de la máquina son los que inician y detienen el to start and stop the machine, select wash movimiento, seleccionan las distintas fórmulas y formulas, and monitor machine operation. vigilan la operación de la máquina. PELLERIN MILNOR CORPORATION... - Seite 112 [Operator signal and signal cancel button] Pantalla de gráficas de cristal líquido [Liquid crystal graphic display] Interruptor de llave para Correr/Programar [Run/Program keyswitch] Teclado [Keypad] Botón para comenzar [Start button] Botón para parar [Stop button] PELLERIN MILNOR CORPORATION...

- Seite 113 De regreso a to allow the machine to run. la posición normal permitirá que la máquina pueda correr nuevamente. Aviso 1 : Presione el botón de parada de Notice 1 : Press the emergency stop button PELLERIN MILNOR CORPORATION...

- Seite 114 Tablero-—Permite al operador comunicarse Keypad—allows the operator to con el sistema de control de la máquina. Este communicate with the machine control tablero está dividido en tres secciones: los system. The keypad is divided into three PELLERIN MILNOR CORPORATION...

-

Seite 115: What Does This Switch Do

Cuando Mildata computer. When set to the Local el interruptor es llevado a Local( position ( ), only formulas present in solamente las fórmulas existentes En la the machine are available. máquina están disponibles. PELLERIN MILNOR CORPORATION... - Seite 116 This optional feature ayudar en los procesos de carga y descarga. optimally positions the basket for access Este dispositivo permite colocar a cada to the selected pocket. compartimiento óptimamente para tener acceso a él, durante la carga y descarga. PELLERIN MILNOR CORPORATION...

- Seite 117 Capítulo 1. Controles Figura [Figure] 8: Interruptor de selección Autospot [Autospot selector switch] — Fin de BICWCO02 — — End of BICWCO02 — PELLERIN MILNOR CORPORATION...

-

Seite 118: Operating Instructions For Plant Personnel

• Do not service the machine unless • No realice ningún servicio a la máquina qualified and authorized. You must a menos que esté calificado y autorizado. clearly understand the hazards and Comprenda claramente los peligros y la how to avoid them. PELLERIN MILNOR CORPORATION... -

Seite 119: Check Switch Settings

Cerciórese que el interruptor Check that the master switch principal esté en is at PELLERIN MILNOR CORPORATION... -

Seite 120: How Do I Load A Staphguard

Capítulo 2. Operación normal ® ¿Cómo yo cargo una máquina How do I Load a StaphGuard 2.1.3. ® StaphGuard Machine? Visualización o acción Explicación Explanation [Display or Action] Abra la puerta externa . Open the outer door. Seleccione el compartimiento de Select a pocket to load. -

Seite 121: Selecting A Local Formula

Use la pantalla para seleccionar una fórmula the Select Local Formula screen (Figure local (Figura 10) y escoja la fórmula más to choose the correct formula for the goods in apropiada para los artículos que piensa lavar. the machine. PELLERIN MILNOR CORPORATION... - Seite 122 PELLERIN MILNOR CORPORATION...

- Seite 123 100 weight units. This option can save a significant amount of water if you enter accurate weights for each load. PELLERIN MILNOR CORPORATION...

-

Seite 124: Selecting A Mildata Formula

Mildata computer. All of these estas fórmulas estarán disponibles para todas las formulas are available to all washer-extractors lavadoras-extractoras que sean parte de la red y that are part of the Mildata network and have posean compatibilidad. compatible hardware. PELLERIN MILNOR CORPORATION... - Seite 125 Después que usted haya recuperado y verificado After you've retrieved and verified the la fórmula, el controlador Mark VI pregunta por formula, the Mark VI controller prompts for la Información del lote previamente any configured batch data. configurada. PELLERIN MILNOR CORPORATION...

-

Seite 126: Entering Mildata Batch Codes

Employee Number—the identifying code identificación del empleado responsable del for the employee responsible for this lote. El empleado puede ser identificado batch. The employee number may be up hasta con cinco (5) números. to five digits long. PELLERIN MILNOR CORPORATION... -

Seite 127: Start The Selected Formula

(see Supplement productos químicos.(vea Complemento PELLERIN MILNOR CORPORATION... -

Seite 128: What Does The Run Display Tell Me

Figure 14. The information Figura 14. La información mostrada aquí es shown here is explained below. explicada abajo. PELLERIN MILNOR CORPORATION... - Seite 129 [Indicator for optional steam and cooldown valves] Gráfica indicadora de la temperatura del baño [Graphic bath temperature indicator] Información sobre la temperatura y nível del baño [Bath temperature and level data] PELLERIN MILNOR CORPORATION...

-

Seite 130: Formula And Step Information

Some of the possible machine states are condiciones están enumeradas en Tabla listed in Table 1. Error messages appear Avisos de errores aparecen inmediatamente immediately below the machine status debajo de la condición de la máquina, cuando message when required. ocurren. PELLERIN MILNOR CORPORATION... -

Seite 131: Bath Temperature And Level

“Steam” appears when the steam vapor se abre aparece el indicador de valve is open, and “Cooldown” appears when “Calentamiento por vapor ” y cuando la opción the cooldown output is enabled. de enfriar es habilitada aparece el indicador de PELLERIN MILNOR CORPORATION... -

Seite 132: Formula Steps And Chemical Injection

(see Figure 15). descargada {vea Figura 15). Use el Use a procedure similar to the one outlined procedimiento similar al descrito más adelante below to unload the goods. para desgargar la canasta. PELLERIN MILNOR CORPORATION... -

Seite 133: For Any End Code

2.1.7.2), the formula una fórmula con el código 3 de is terminated and cannot be finalizar (vea Sección 2.1.7.2), resumed. la fórmula se terminará y no podrá ser reanudada. Abre la puerta para descargar. Open the door for unloading. PELLERIN MILNOR CORPORATION... -

Seite 134: For End Code 3 (Tumbling)

La acción Tumbling continues for giratoria (tumbling) continúa another two minutes, or until por otros dos minutos a menos you press que usted presione a — Fin de BICWCO03 — — End of BICWCO03 — PELLERIN MILNOR CORPORATION... -

Seite 135: Operator Intervention

Figura 16 muestra como el error on the display. aparece en la pantalla cuando un interruptor protector contra vibración excesiva desactiva el circuito de tres alambres. PELLERIN MILNOR CORPORATION... - Seite 136 La máquina puede controlar un sistema de This machine can control an automatic inyección automática de productos químicos o chemical pump system, or it can signal you puede avisarte para que los agregues to add chemicals manually. The display PELLERIN MILNOR CORPORATION...

- Seite 137 La pantalla cambia para recordarte el operator signal. producto químico que tienes que agregar, pero el conteo regresivo comienza después que la señal para el operador es cancelada. PELLERIN MILNOR CORPORATION...

- Seite 138 After you've added the chemical, químico Cancela la señal para el cancels the operator signal operador y empieza el conteo and starts the injection time del tiempo de inyección counter. — Fin de BICWCT04 — — End of BICWCT04 — PELLERIN MILNOR CORPORATION...

- Seite 139 Türk...

- Seite 141 Milnor veya aracıları ya da çalışanları, bu el kitabının İngilizce olmayan sürümünün kullanılması veya kullanılamaması ya da bu el kitabına güvenilmesi sonucu herhangi bir şekilde ortaya çıkabilecek veya çevirideki yanlışlıklardan, eksikliklerden ya da hatalardan kaynaklanan...

- Seite 142 Uygulanabilir Milnor Model numarasına göre ürünler: [Applicable ® Milnor products by model number:] ® 42044SP2 42044SP3 60044SP2 60044SP3 72044SP2...

- Seite 143 2.1. Tesis personeli için İşletme Talimatı (Doküman BICWCO03) 2.1.1. Güvenlik için buradan başlayın 2.1.2. Switch set değerlerini kontrol edin. ® 2.1.3. StaphGuard Makineyi nasıl yüklerim? 2.1.4. Formula/program nasıl seçerim? Rakam 9: Seçim Local veya Remote Formula [Selecting a Local or Remote Formula] 2.1.4.1.

- Seite 144 (Doküman BICWCT04) 3.1.1. Operatör sinyali ile Hata Rakam 16: Operatör sinyali ile Tipik Hata [Typical Error with Operator Signal] 3.1.2. Kimyasal için Operatör Sinyali Rakam 17: Çalıştır ekranında Kimyasal enjeksiyon Görünümü [Chemical Injection View on Run Display] PELLERIN MILNOR CORPORATION...

- Seite 145 (Document BICWCO03) 2.1.1. Start Here for Safety 2.1.2. Check Switch Settings ® 2.1.3. How do I Load a StaphGuard Machine? 2.1.4. How do I Select a Formula? Figure 9: Seçim Local veya Remote Formula [Selecting a Local or Remote Formula] 2.1.4.1.

-

Seite 146: 3.1.2. Operator Signal For A Chemical

(Document BICWCT04) 3.1.1. Error with Operator Signal Figure 16: Operatör sinyali ile Tipik Hata [Typical Error with Operator Signal] 3.1.2. Operator Signal for a Chemical Figure 17: Çalıştır ekranında Kimyasal enjeksiyon Görünümü [Chemical Injection View on Run Display] PELLERIN MILNOR CORPORATION... -

Seite 147: Controls On Mark Vi Non-Tilting Washer-Extractors

üzerinde yerleştirilmiştir (Rakam are located on the front control panel (Figure Diğer ilave kontroller aşağıda tarif edildiği gibi 1). Additional controls and connections are makinenin değişik yerlerine yerleştirilmişlerdir. located elsewhere on the machine, as described here. PELLERIN MILNOR CORPORATION... -

Seite 148: Where Do I Connect The Data Storage Device

Rakam 2 de gösterildiği data transfer device to save or restore gibi etiketlenmiş olan, bu bağlantıyı kullanın. machine programming and configuration memory. Rakam [Figure] 2: Veri transferi için paralel Bağlantı [Serial Connection for Data Transfer] PELLERIN MILNOR CORPORATION... -

Seite 149: What Are The Operating Controls

[Master switch for power] Operatör sinyali ve sinyal iptal buton [Operator signal and signal cancel button] Likit Kristal Grafik Ekranı [Liquid crystal graphic display] Run/Program anahtarı [Run/Program keyswitch] Klavye [Keypad] Başla buton [Start button] Stop buton [Stop button] PELLERIN MILNOR CORPORATION... - Seite 150 Notice 1 : Press the emergency stop derhal basınız. Bu üç faz akımını kesecektir. button immediately in any emergency Böylece makine duracak ve drenaj açılacaktır. situation. This disables the 3-wire circuit, which stops all machine operation and causes PELLERIN MILNOR CORPORATION...

- Seite 151 Bazı Each button may perform more than one tuşlar da başka tuşlarla birlikte kullanılarak function, based on the current machine ilave fonksiyonlar yaratılabilir. status. Some buttons are also used in combinations for additional functions. PELLERIN MILNOR CORPORATION...

-

Seite 152: What Does This Switch Do

), only formulas present in the machine are available. Rakam [Figure] 6: Mildata/Yerel Tercih sviçi [Mildata/Local Selector switch] Manuel ikmal püskürtme butonu (Rakam Manual supply flush button (Figure 7)— 7)—Opsiyonel püskürtme enjeksiyon On machines equipped with an optional PELLERIN MILNOR CORPORATION... - Seite 153 özellik otomatik olarak tamburun optimally positions the basket for access içinde çalışılacak kısmının pozisyonunu to the selected pocket. düzenler. Rakam [Figure] 8: Otomatik tambur Seçim Sviçi [Autospot selector switch] — Sonu BICWCO02 — — End of BICWCO02 — PELLERIN MILNOR CORPORATION...

-

Seite 154: Normal Operation

• Do not service the machine unless • Bilgisiz ve yetkisiz durumda müdahale qualified and authorized. You must etmeyiniz. Tehlikelerin açıkça farkında clearly understand the hazards and olmalısınız ve nasıl yok edileceğini how to avoid them. bilmelisiniz. PELLERIN MILNOR CORPORATION... -

Seite 155: Check Switch Settings

Ana şalterin pozisyonda Check that the master switch olmasını sağla. is at ® ® StaphGuard Makineyi nasıl How do I Load a StaphGuard 2.1.3. yüklerim? Machine? Göster veya uygula Açıklama Explanation [Display or Action] Bu Dış kapıyı açın. Open the outer door. -

Seite 156: How Do I Select A Formula

Formulalardan) herhangi biri seçilebilir. Bu Seç the Select Local Formula screen (Figure Local Formula ekranını kullanın (Rakam to choose the correct formula for the goods makine içindeki malları doğru programla in the machine. (Formula ile) yıkamak için. PELLERIN MILNOR CORPORATION... - Seite 157 , böylece column as the selection box, aşağı yukarı okları kullanarak you can use these two keys seçim kutusundan istenen to move the selection box Formula seçilebilir. down or up to select the formula. PELLERIN MILNOR CORPORATION...

- Seite 158 100 weight units. This option can doğru olarak girilirse. save a significant amount of water if you enter accurate weights for each load. PELLERIN MILNOR CORPORATION...

-

Seite 159: Selecting A Mildata Formula

Bütün bu yıkama formulas on the Mildata computer. All of these programları Mildata ağına bağlı ve uygun cihazlara formulas are available to all washer-extractors sahipseniz ulaşabilirsiniz. that are part of the Mildata network and have compatible hardware. PELLERIN MILNOR CORPORATION... -

Seite 160: Entering Mildata Batch Codes

(see Dökümandaki ilgili bölüm BICWCC01). Girilen the related section in document veriler Mildata Komputerine hesap ve rapor BICWCC01). The data you enter is sent to oluşumu için aktarılır. the Mildata computer for accounting and report generation. PELLERIN MILNOR CORPORATION... - Seite 161 İstediğiniz zamanda girilen bu might represent a particular route number değer birçok hesabı kapsayacak rotayı temsil common to several accounts. A lot etmelidir. Lot numarası on dijitli rakam number can be up to 10 digits long. PELLERIN MILNOR CORPORATION...

-

Seite 162: Start The Selected Formula

While the machine is running the formula gösterilene benzer şekilde görülür Rakam you selected, the display appears similar to Ekranda gösterilen bilgiler aşağıda the one shown in Figure 14. The information açıklanmıştır. shown here is explained below. PELLERIN MILNOR CORPORATION... - Seite 163 Su valfleri endikatörü [Water valves indicators] Opsiyonel buhar ve soğutma valfleri endikatörü [Indicator for optional steam and cooldown valves] Grafik banyo sıcaklık endikatörü [Graphic bath temperature indicator] Banyo sıcaklığı ve seviye verisi [Bath temperature and level data] PELLERIN MILNOR CORPORATION...

-

Seite 164: Formula And Step Information

Muhtemel bazı makine durum mesajları Tablo 1 time. Some of the possible machine states are listelenmiştir.Hata mesajı anında istenildiğinde listed in Table 1. Error messages appear makine durum mesajının altında görülebilir. immediately below the machine status message when required. PELLERIN MILNOR CORPORATION... -

Seite 165: Basket Rotation

Dikey endikatör percentage of the desired level that's barı programlanan seviyeye ulaşıldığında sabit achieved. The vertical indicator bar is solid mavi olur ve bu tamamen beyaz olduğunda blue when the programmed level is achieved, PELLERIN MILNOR CORPORATION... -

Seite 166: Formula Steps And Chemical Injection

(see Figure 15). belirtilen boşaltma prosedürüne göre boşaltınız. Use a procedure similar to the one outlined below to unload the goods. Rakam [Figure] 15: Formula biterken tipik mesaj [Typical Message when Formula Ends] PELLERIN MILNOR CORPORATION... -

Seite 167: For Any End Code

(bak Bölüm 2.1.7.2), formula with end code 3 (see bu durmda Formula iptal olur Section 2.1.7.2), the formula ve tekrar gerei döndürülemez. is terminated and cannot be resumed. Boşaltma için kapıyı açınız. Open the door for unloading. PELLERIN MILNOR CORPORATION... -

Seite 168: For End Code 3 (Tumbling)

Yuvarlama işlemi iki Tumbling continues for dakika daha, veya ‘e another two minutes, or until basıncaya kadar devam eder. you press — Sonu BICWCO03 — — End of BICWCO03 — PELLERIN MILNOR CORPORATION... -

Seite 169: Operator Intervention

Figure 16 kaynaklanabilir. Rakam 16 bu vibrasyon shows how a vibration switch error appears hatalarının ekranda nasıl görüleceğini gösterir. on the display. PELLERIN MILNOR CORPORATION... -

Seite 170: Operator Signal For A Chemical

ötmesi yöntemi ile to add chemicals manually. The display uyarabilir. Bu (Rakam 17) gösterge her iki (Figure 17) appears the same in either case, PELLERIN MILNOR CORPORATION... - Seite 171 Kimyasalı ilave ettikten sonra, After you've added the chemical, Operatör sinyalini iptal et ve cancels the operator signal enjeksiyon zaman sürecini and starts the injection time başlat. counter. — Sonu BICWCT04 — — End of BICWCT04 — PELLERIN MILNOR CORPORATION...

- Seite 173 Polski...

- Seite 175 Firma Milnor nie podjęła prób sprawdzenia informacji zawartych w wersji językowej innej niż angielska, gdyż tłumaczenie zostało w całości wykonane przez stronę trzecią. Dlatego też firma Milnor nie odpowiada za błędy związane z treścią lub formą niniejszej instrukcji i zrzeka się...

- Seite 176 Stosowane Milnor produkty wg modelu: [Applicable Milnor ® ® products by model number:] 42044SP2 42044SP3 60044SP2 60044SP3 72044SP2...

- Seite 177 BICWCO03) 2.1.1. Ważne informacje dotyczące bezpieczeństwa 2.1.2. Sprawdzanie ustawienia przełączników ® 2.1.3. Sposób ładowania urządzenia StaphGuard 2.1.4. Sposób wybrania formuły Rysunek 9: Wybór formuły Local (Lokalny) lub Remote (Zdalny) 2.1.4.1. Wybór formuły Local (Lokalny) Rysunek 10: Ekran Select Local Formula (Wybierz formułę...

- Seite 178 Działanie podejmowane przez operatora (Dokument BICWCT04) 3.1.1. Błąd wskazywany generowaniem sygnału dla operatora Rysunek 16: Typowe błędy wskazywane generowaniem sygnału dla operatora 3.1.2. Generowanie sygnału dla operatora z powodu środka Rysunek 17: Widok wstrzyknięcia środka chemicznego chemicznego na ekranie pracy PELLERIN MILNOR CORPORATION...

- Seite 179 (Document BICWCO03) 2.1.1. Start Here for Safety 2.1.2. Check Switch Settings ® 2.1.3. How do I Load a StaphGuard Machine? 2.1.4. How do I Select a Formula? Figure 9: Selecting a Local or Remote Formula 2.1.4.1. Selecting a Local Formula...

- Seite 180 For End Code 3 (Tumbling) Chapter 3. Signals and Errors 3.1. Operator Intervention (Document BICWCT04) 3.1.1. Error with Operator Signal Figure 16: Typical Error with Operator Signal 3.1.2. Operator Signal for a Chemical Figure 17: Chemical Injection View on Run Display PELLERIN MILNOR CORPORATION...

-

Seite 181: Rozdział 1. Elementy Sterowania

(Figure sterowania (Rysunek 1). Dodatkowe elementy 1). Additional controls and connections are sterowania i złącza umieszczone są w innym miejscu located elsewhere on the machine, as godnie z poniższym opisem. described here. PELLERIN MILNOR CORPORATION... -

Seite 182: Where Do I Connect The Data Storage Device

2, with a serial zapisać lub przywrócić program urządzenia i pamięć data transfer device to save or restore konfiguracyjną. machine programming and configuration memory. Rysunek [Figure] 2: Złącze szeregowe do transmisji danych [Serial Connection for Data Transfer] PELLERIN MILNOR CORPORATION... -

Seite 183: What Are The Operating Controls

Przycisk Sygnał dla operatora i Anulowanie sygnału [Operator signal and signal cancel button] Wyświetlacz ciekłokrystaliczny elementów graficznych [Liquid crystal graphic display] Przełącznik pracy/programowania [Run/Program keyswitch] Blok klawiszy [Keypad] Przycisk Start (Rozpoczęcie) [Start button] Przycisk Zatrzymanie [Stop button] PELLERIN MILNOR CORPORATION... - Seite 184 Notice 1 : Press the emergency stop Uwaga 1 : W sytuacji awaryjnej należy natychmiast nacisnąć przycisk zatrzymania button immediately in any emergency awaryjnego. Zostanie odłączony obwód 3-żyłowy, co situation. This disables the 3-wire circuit, PELLERIN MILNOR CORPORATION...

- Seite 185 Każdy przycisk może mieć buttons, and function-specific buttons. zaprogramowanych kilka funkcji w zależności od Each button may perform more than one aktualnego stanu urządzenia. Niektóre przyciski function, based on the current machine są także używane w kombinacjach, dzięki czemu PELLERIN MILNOR CORPORATION...

-

Seite 186: Funkcja Przełącznika

Local (Lokalny) ( _ ) dostępne są tylko formuły zapisane w urządzeniu. Mildata computer. When set to the Local position ( ), only formulas present in the machine are available. PELLERIN MILNOR CORPORATION... - Seite 187 Autospot feature to aid in loading wspomagającą ładowanie i rozładunek. Ta and unloading. This optional feature opcjonalna funkcja optymalnie ustawia bęben w optimally positions the basket for access celu zapewnienia dostępu do wybranej kieszeni. to the selected pocket. PELLERIN MILNOR CORPORATION...

- Seite 188 Rozdział 1. Elementy sterowania Rysunek [Figure] 8: Przełącznik wyboru Autospot [Autospot selector switch] — Koniec BICWCO02 — — End of BICWCO02 — PELLERIN MILNOR CORPORATION...

-

Seite 189: Rozdział 2. Normalna Eksploatacja

• Serwisowania urządzenia nie powinny • Do not service the machine unless podejmować się osoby niewykwalifikowane i qualified and authorized. You must nieuprawnione. Należy zapoznać się z clearly understand the hazards and zagrożeniami oraz sposobami ich unikania. how to avoid them. PELLERIN MILNOR CORPORATION... -

Seite 190: Check Switch Settings

Check that the master switch Sprawdzić, czy wyłącznik główny is at znajduje się w położeniu M . ® How do I Load a StaphGuard Sposób ładowania urządzenia 2.1.3. ® taphGuard Machine? Display or Action Wyjaśnienie... -

Seite 191: How Do I Select A Formula

Use Formula (Wybierz formułę trybu lokalnego) the Select Local Formula screen (Figure (Rysunek 10), aby wybrać prawidłową formułę dla to choose the correct formula for the goods in rodzaju ładunku urządzenia. the machine. PELLERIN MILNOR CORPORATION... - Seite 192 żądanej formuły. down or up to select the formula. PELLERIN MILNOR CORPORATION...

- Seite 193 Ta opcja może zaoszczędzić znaczą entered 100 weight units. This option can ilość wody po wprowadzeniu dokładnej wagi save a significant amount of water if you każdego ładunku. enter accurate weights for each load. PELLERIN MILNOR CORPORATION...

-

Seite 194: Selecting A Mildata Formula

Mildata computer. All of these formuły są dostępne dla każdej pralki-wirówki, która formulas are available to all washer-extractors jest są częścią sieci Mildata i jest wyposażona w that are part of the Mildata network and have kompatybilny sprzęt. compatible hardware. PELLERIN MILNOR CORPORATION... - Seite 195 (patrz the related section in document the related section in document BICWCC01). BICWCC01). Wprowadzone dane są wysyłane do The data you enter is sent to the Mildata komputera Mildata w celu zaksięgowania i computer for accounting and report utworzenia raportu. generation. PELLERIN MILNOR CORPORATION...

- Seite 196 A lot klientów. Numer partii może składać się z number can be up to 10 digits long. maksymalnie 10 cyfr. PELLERIN MILNOR CORPORATION...

-

Seite 197: Start The Selected Formula

While the machine is running the formula wyświetlany jest ekran (podobny: Rysunek 14). you selected, the display appears similar to Wyświetlane informacje zostały wyjaśnione poniżej. the one shown in Figure 14. The information shown here is explained below. PELLERIN MILNOR CORPORATION... -

Seite 198: Formula And Step Information

The step number and name of the current są numer i nazwa aktualnego kroku. Kontroler Mark step are displayed to the right of the formula VI aktualizuje numer formuły i nazwę po information. The Mark VI controller updates rozpoczęciu formuły oraz na początku każdego PELLERIN MILNOR CORPORATION... - Seite 199 Tablica time. Some of the possible machine states are Komunikaty o błędach są wyświetlane natychmiast listed in Table 1. Error messages appear poniżej komunikatu o stanie urządzenia. immediately below the machine status message when required. PELLERIN MILNOR CORPORATION...

-

Seite 200: Basket Rotation

Po when either of these optional features is otwarciu zaworu pary wyświetlany jest napis “Steam enabled. “Steam” appears when the steam (Para)”, a po włączeniu opcji schładzania napis valve is open, and “Cooldown” appears when “Cooldown (Schładzanie)”. PELLERIN MILNOR CORPORATION... -

Seite 201: Kroki Formuły I Wstrzyknięcie Środka Chemicznego

Aby rozładować urządzenie należy wykonać Use a procedure similar to the one outlined rocedurę zbliżoną do opisanej poniżej. below to unload the goods. Rysunek [Figure] 15: Typowe komunikaty wyświetlane po zakończeniu formuły [Typical Message when Formula Ends] PELLERIN MILNOR CORPORATION... - Seite 202 Section 2.1.7.2), the formula pomocą kodu zakończenia 3 (patrz is terminated and cannot be Rozdział 2.1.7.2) powoduje resumed. zakończenie formuły. Nie jest możliwe jej wznowienie. Open the door for unloading. Otworzyć drzwi w celu rozładowania. PELLERIN MILNOR CORPORATION...

-

Seite 203: Dla Kodu Zakończenia Nr 3 (Obracanie Bębna )

Tumbling continues for Obracanie bębna jest another two minutes, or until kontynuowane przez kolejne dwie you press minuty lub do naciśnięcia przycisku l . — Koniec BICWCO03 — — End of BICWCO03 — PELLERIN MILNOR CORPORATION... -

Seite 204: Rozdział 3. Sygnały I Błędy

Figure 16 przemiennika, który steruje silnikiem. Rysunek 16 shows how a vibration switch error appears przedstawia błąd przełącznika wibracji wyświetlany on the display. a ekranie. PELLERIN MILNOR CORPORATION... -

Seite 205: Operator Signal For A Chemical

Chemical hemicznego To urządzenie może sterować automatycznym This machine can control an automatic układem pompy środka chemicznego lub chemical pump system, or it can signal you sygnalizować o konieczności ręcznego dodania to add chemicals manually. The display PELLERIN MILNOR CORPORATION... - Seite 206 Po dodaniu środka chemicznego After you've added the chemical, cancels the operator signal należy anulować sygnał dla and starts the injection time operatora i uruchomić licznik czasu counter. wstrzyknięcia. — Koniec BICWCT04 — — End of BICWCT04 — PELLERIN MILNOR CORPORATION...

- Seite 207 Deutsch...

- Seite 209 Milnor hat darüber hinaus keinen Versuch unternommen, die in der nichtenglischen Version enthaltenen Informationen zu prüfen, da diese vollständig durch Dritte erstellt wurde. Milnor ist daher ausdrücklich nicht für inhaltliche oder formale Fehler haftbar und trägt keine Verantwortung für das Vertrauen auf, oder die Folgen der Verwendung von, Informationen in der nichtenglischen Version.

- Seite 210 Anwendbare Milnor ® Maschinen der Modelle: [Applicable Milnor ® products by model number:] 42044SP2 42044SP3 60044SP2 60044SP3 72044SP2...

- Seite 211 Wo schließe ich ein Gerät für den Datentransfer an? Abbildung 2: Serielle Anschluss für den Datenaustausch 1.1.3. Was sind die Betriebssteuerelemente? Abbildung 3: Mark VI StaphGuard, Steuerelemente auf der Schmutzseite Abbildung 4: Tastenfeld Abbildung 5: Typische Steuerelemente für die Staph-Abdeckung auf der sauberen Seite 1.1.4.

- Seite 212 Für einige Endcode 2.1.7.2. Für den Endcode 3 (Auflockern) Kapitel 3. Signale und Fehler 3.1. Benutzereinschreiten (Dokument BICWCT04) 3.1.1. Fehler mit Signal Abbildung 16: Typischer Fehler mit Signal 3.1.2. Signal für Waschmittel Abbildung 17: Waschmitteleinspülungsanzeige auf dem Betriebsdisplay PELLERIN MILNOR CORPORATION...

- Seite 213 (Document BICWCO03) 2.1.1. Start Here for Safety 2.1.2. Check Switch Settings ® 2.1.3. How do I Load a StaphGuard Machine? 2.1.4. How do I Select a Formula? Figure 9: Selecting a Local or Remote Formula 2.1.4.1. Selecting a Local Formula...

- Seite 214 For End Code 3 (Tumbling) Chapter 3. Signals and Errors 3.1. Operator Intervention (Document BICWCT04) 3.1.1. Error with Operator Signal Figure 16: Typical Error with Operator Signal 3.1.2. Operator Signal for a Chemical Figure 17: Chemical Injection View on Run Display PELLERIN MILNOR CORPORATION...

-

Seite 215: Kapitel 1. Steuerelemente

Bedienfeld [Control panel] Manuelle Spültaste [Manual supply flush button] Hydraulik Mannometer für die Ladetür [Hydraulic pressure gauge for loading door] Luftdruck Mannometer für Kippsystem (hinter der unteren Abdeckung) [Air pressure gauge for tilt system (behind lower rear panel)] PELLERIN MILNOR CORPORATION... -

Seite 216: Wo Schließe Ich Ein Gerät Für Den Datentransfer An

The primary operating controls are required erforderlich, um die Maschine zu starten und zu to start and stop the machine, select wash stoppen, das Waschprogramm zu wählen und den formulas, and monitor machine operation. etrieb der Maschine zu überwachen. PELLERIN MILNOR CORPORATION... - Seite 217 Kapitel 1. Steuerelemente Abbildung [Figure] 3: Mark VI StaphGuard, Steuerelemente auf der Schmutzseite [Mark VI Staph Guard Soil Side Controls] Bedienfeld [Control Panel] Legende [Legend] Notstopp Taste [Emergency stop button] Türentriegelung Taste [Door unlock button] Wahlschalter Jog/Autospot (Schrittbetrieb/Autospot) Schalter [Jog/Autospot...

- Seite 218 Notice 1 : Press the emergency stop die Notaus Taste. Der Sicherheitsstromkreis wird button immediately in any emergency unterbrochen, stoppt den Betrieb der Maschine und situation. This disables the 3-wire circuit, ermöglicht es, den Abfluss zu öffnen. PELLERIN MILNOR CORPORATION...

- Seite 219 Funktion haben, basierend auf dem Each button may perform more than one gegenwärtigen Maschinenstatus. Einige Tasten function, based on the current machine werden auch in Kombination für zusätzliche status. Some buttons are also used in Funktionen benutzt. PELLERIN MILNOR CORPORATION...

-

Seite 220: Was Macht Dieser Schalter

Mildata computer. When set to the Local Programme gezeigt, die in der Maschine position ( ), only formulas present in verfügbar sind. the machine are available. Abbildung [Figure] 6: Mildata/Lokal-Schalter [Mildata/Local Selector switch] Manuelle Spültaste (Abbildung 7)—Bei Maschinen Manual supply flush button (Figure PELLERIN MILNOR CORPORATION... - Seite 221 This optional feature positioniert exakt die ausgewählte Kammer der optimally positions the basket for access Trommel. to the selected pocket. Abbildung [Figure] 8: Autospot Auswahlschalter [Autospot selector switch] — Ende BICWCO02 — — End of BICWCO02 — PELLERIN MILNOR CORPORATION...

-

Seite 222: Kapitel 2. Normalbetrieb

• Do not service the machine unless Strom mehr an der Maschine anliegt. qualified and authorized. You must • Die Maschine darf ausschließlich von clearly understand the hazards and qualifiziertem und autorisiertem Personal how to avoid them. PELLERIN MILNOR CORPORATION... -

Seite 223: Überprüfen Sie Die Schalterstellungen

Position Bereit sein. Check that the master switch Stellen Sie sicher, dass der Hauptschalter auf M steht. is at ® ® Beladen einer StaphGuard How do I Load a StaphGuard 2.1.3. aschine Machine? Anzeige oder Aktion Erklärung Explanation [Display or Action] Open the outer door. -

Seite 224: Wie Wähle Ich Ein Programm

Use Benutzen Sie den Wählen Sie lokales Programm the Select Local Formula screen (Figure Bildschirm (Abbildung 10) um das gewünschte to choose the correct formula for the goods in Programm aufzurufen. the machine. PELLERIN MILNOR CORPORATION... - Seite 225 Spalte wie das you can use these two keys Auswahlkästchen, können Sie diese to move the selection box beiden Tasten benutzen, um das down or up to select the Kästchen hoch- oder formula. runterzubewegen. PELLERIN MILNOR CORPORATION...

- Seite 226 Eingabe des Gewichts kann eine beträchtliche entered 100 weight units. This option can Menge Wasser gespart werden. save a significant amount of water if you enter accurate weights for each load. PELLERIN MILNOR CORPORATION...

-

Seite 227: Auswählen Eines Mildata Programms

Computer speichern. Alle dieser Programme sind für formulas are available to all washer-extractors alle Wasch/Schleudermaschinen verfügbar, die Teil that are part of the Mildata network and have des Mildata Netzwerks sind und kompatible compatible hardware. Hardware haben. PELLERIN MILNOR CORPORATION... -

Seite 228: Mildata Batchcodes" Eingeben

Felder (batch data fields) vorauszusagen. Die the related section in document BICWCC01). eigegebenen Daten werden zum Mildatacomputer The data you enter is sent to the Mildata gesendet, um eine Übersicht zu erstellen. computer for accounting and report generation. PELLERIN MILNOR CORPORATION... - Seite 229 Wert kann eine bestimmte might represent a particular route number Routenummer gemeinsam für verschiedene common to several accounts. A lot Konten repräsentieren. Die Anzahl kann zehn number can be up to 10 digits long. Stellen lang sein. PELLERIN MILNOR CORPORATION...

-

Seite 230: Starten Sie Das Gewählte Programm

While the machine is running the formula Display ähnlich wie in dem gezeigten Abbildung you selected, the display appears similar to Die hier gezeigte Information ist unten erklärt. the one shown in Figure 14. The information shown here is explained below. PELLERIN MILNOR CORPORATION... -

Seite 231: Programm Und Schrittinformation

Nummer. number. Die Schrittnummer und Name des laufenden Schritts The step number and name of the current werden rechts neben der Programminformation step are displayed to the right of the formula angezeigt. Die Mark VI Steuerung aktualisiert PELLERIN MILNOR CORPORATION... - Seite 232 Zeit. Einige der möglichen Maschinenzustände sind time. Some of the possible machine states are Tabelle 1 aufgeführt. Fehlermeldungen erscheinen listed in Table 1. Error messages appear sofort unterhalb der Maschinenstatus Nachricht, falls immediately below the machine status rforderlich. message when required. PELLERIN MILNOR CORPORATION...

-

Seite 233: Trommelrotation -Der Trommelrotationsgrafik

Die Grafik Wasserlevel Anzeiger zeigt den The graphic bath level indicator shows the Prozentsatz des gewünschten Levels, das erreicht ist. percentage of the desired level that's Der senkrechte Anzeigenstab ist blau, wenn das PELLERIN MILNOR CORPORATION... -

Seite 234: Programmschritte Und Waschmitteleinspülung

(see Figure 15). sie die Maschine wie unten dar gestellt. Use a procedure similar to the one outlined below to unload the goods. Abbildung [Figure] 15: Typische Nachricht, wenn ein Programm stoppt [Typical Message when Formula Ends] PELLERIN MILNOR CORPORATION... -

Seite 235: Für Einige Endcode -Die Mark Vi Steuerung

2.1.7.2) zu stoppen, ist formula with end code 3 (see das Programm abgebrochen und Section 2.1.7.2), the formula kann nicht wiederaufgenommen is terminated and cannot be werden. resumed. Open the door for unloading. Öffnen Sie die Tür zum Entladen. PELLERIN MILNOR CORPORATION... -

Seite 236: Für Den Endcode 3 (Auflockern)

Signal wieder auf. Es wird für Tumbling continues for weitere zwei Minuten aufgelockert, oder bis Sie l drücken. another two minutes, or until you press — Ende BICWCO03 — — End of BICWCO03 — PELLERIN MILNOR CORPORATION... -

Seite 237: Kapitel 3. Signale Und Fehler

Funktionsstörung des Inverters, der den Motor inverter that controls the motor. Figure 16 steuert. Abbildung 16 zeigt, wie ein vibration shows how a vibration switch error appears Schalterfehler auf dem Display erscheint. on the display. PELLERIN MILNOR CORPORATION... -

Seite 238: Signal Für Waschmittel

Sie Waschmittel manuell to add chemicals manually. The display hinzufügen müssen. Das Display (Abbildung (Figure 17) appears the same in either case, erscheint in jedem Fall, aber das Arbeitersignal ertönt but the operator signal sounds only if the PELLERIN MILNOR CORPORATION... - Seite 239 Nachdem Sie das Waschmittel hinzugefügt haben, After you've added the chemical, cancels the operator signal Bricht das Signal ab und startet den and starts the injection time Einspülzeitzähler. counter. — Ende BICWCT04 — — End of BICWCT04 — PELLERIN MILNOR CORPORATION...