Inhaltszusammenfassung für Krone KWT 7.82/6x7

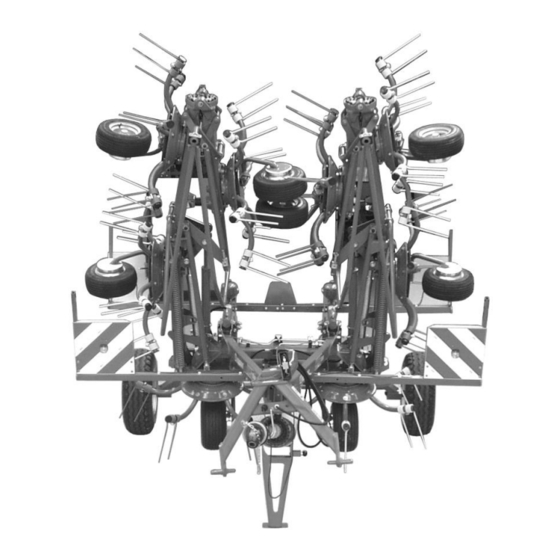

- Seite 1 Rotary tedder KWT 7.82/6x7 KWT 8.82/8 KWT 11.22/10 (from serial no.: 803 269) Order no.: 150 000 104 04 en 01.04.2013...

-

Seite 2: Ec Declaration Of Conformity

Krone rotary tedder Machine: Type / Types: KWT 7.82/6x7; KWT 8.82/8; KWT 11.22/10 to which this declaration refers is in compliance with the relevant provisions of EC Directive 2006/42/EC (Machinery) The signing Managing Director is authorised to compile the technical documents. -

Seite 3: Inhaltsverzeichnis

Table of Contents Pos: 4 /Überschriften/Überschriften 1/F-J/Inhaltsverzeichnis @ 31\mod_1251969952727_78.docx @ 302165 @ 1 @ 1 Table of Contents Pos: 5 /BA/Inhaltsverzeichnis Sprachenneutral @ 10\mod_1221574899104_0.docx @ 135495 @ @ 1 Table of Contents ........................... 3 Foreword ..............................6 Introduction ............................. 7 Purpose of Use .......................... - Seite 4 Table of Contents Lighting Connection ......................... 34 Driving and Transport .......................... 35 Preparation for transport ........................36 Mounting the Safety Chain to the Tractor ..................38 Install safety chain on the machine ....................38 Operation ............................... 39 Overload protection ......................... 39 From transport into working position ....................

- Seite 5 Table of Contents 14.2 At the End of the Harvest Season ....................80 14.3 Before the Start of the New Season ....................81 14.4 Special Safety Instructions ......................81 Index ..............................82 Pos: 6 /BA/---------------Seitenumbruch---------------- @ 0\mod_1196175311226_0.docx @ 4165 @ @ 1...

-

Seite 6: Foreword

Pos: 7.2 /BA/Vorwort/Wender/Verehrter Kunde Wender @ 13\mod_1225877243008_78.docx @ 164284 @ @ 1 Dear Customer! By purchasing your rotary tedder , you have acquired a quality product from KRONE. We are grateful for the confidence you have invested in us in buying this machine. -

Seite 7: Introduction

Introduction Pos: 9.1 /BA/Einleitung/Einleitung @ 0\mod_1195562498677_78.docx @ 416 @ 1 @ 1 Introduction These operating instructions contain fundamental instructions. These must be observed in operation and maintenance. For this reason, these operating instructions must be read by operating personnel before commissioning and use, and must be available for easy reference. Follow both the general safety instructions contained in the section on safety and the specific safety instructions contained in the other sections. -

Seite 8: Information Required For Questions And Orders

Note Authentic KRONE spare parts and accessories authorised by the manufacturer help to ensure safety. The use of spare parts, accessories or additional equipment not manufactured, tested or approved by KRONE will exclude any liability for consequential damage. -

Seite 9: Technical Data

We reserve the right to make design changes at any time and without notification of reasons. Pos: 9.14 /BA/Einleitung/Technische Daten/Wender/KWT 8.82 bis 11.22 @ 153\mod_1363246056632_78.docx @ 1364765 @ @ 1 Type KWT 7.82/6x7 KWT 8.82/8 KWT 11.22/10 Working width [mm] 7.800... -

Seite 10: Safety

Safety Pos: 12.1 /Überschriften/Überschriften 1/P-T/Sicherheit @ 0\mod_1195566748646_78.docx @ 635 @ 1 @ 1 Safety Pos: 12.2 /BA/Sicherheit/Wender/Sicherheit Einführung Wender @ 13\mod_1225982797078_78.docx @ 165259 @ 2 @ 1 Introduction The rotary tedder is equipped with all safety devices (protective devices). However, it is not possible to eliminate all potential hazards on this machine as this would impair its full functional capability. -

Seite 11: Re-Ordering The Adhesive Safety And Information Labels

The surface for affixing the adhesive label must be clean and free of dirt, oil and grease. Pos: 12.6 /Überschriften/Überschriften 3/A-E/Ansprechpartner @ 0\mod_1195569394286_78.docx @ 839 @ 3 @ 1 4.1.3 Contact Pos: 12.7 /Adressen/Adresse Maschinenfabrik KRONE Spelle @ 0\mod_1195568531083_78.docx @ 734 @ @ 1 Maschinenfabrik Bernard Krone GmbH Heinrich-Krone-Strasse 10 D-48480 Spelle (Germany) Telephone: + 49 (0) 59 77/935-0 (Head Office) Fax.: + 49 (0) 59 77/935-339 (Head Office) -

Seite 12: Position Of The Adhesive Safety Stickers On The Machine

Safety Pos: 12.9 /Überschriften/Überschriften 2/K-O/Lage der Sicherheitsaufkleber an der Maschine @ 0\mod_1195634967326_78.docx @ 1020 @ 2 @ 1 Position of the Adhesive Safety Stickers on the Machine Pos: 12.10 /BA/Sicherheit/Aufkleber/Wender/Bild Sicherheitsaufkleber KWT 8.82 bis 11.22 @ 22\mod_1239955002722_78.docx @ 235150 @ @ 1 KWT8828002_1 Fig. - Seite 13 Order no. 942 196-1 (6x) 942 196 -1 Order No. 939 529-0 (1x) KWT 11.22/10 (3x) KWT 8.82/8 (3x) KWT 7.82/6x7 Only with hydraulic spread limiter! Pos: 12.13 /BA/---------------Seitenumbruch---------------- @ 0\mod_1196175311226_0.docx @ 4165 @ @ 1...

-

Seite 14: Identifying Symbols In The Operating Instructions

Safety Pos: 12.14 /BA/Sicherheit/Überarbeitete Warnhinweise/Kennzeichnung von Hinweisen in der Betriebsanleitung Einführungstext (2012-07-27 09:59:06) @ 0\mod_1195637804826_78.docx @ 1098 @ 2 @ 1 Identifying Symbols in the Operating Instructions The safety instructions contained in this manual which could result in personal injury if not followed are identified by the general danger sign: Pos: 12.15 /BA/Sicherheit/Überarbeitete Warnhinweise/Kennzeichnung der Gefahrenhinweise (2012-07-26 15:10:30) @ 28\mod_1250244370070_78.docx @ 274714 @ 2 @ 1 Identification of the hazard warnings... -

Seite 15: Personnel Qualification And Training

Safety Pos: 12.18.1 /BA/Sicherheit/Personalqualifikation und -schulung @ 0\mod_1195639383185_78.docx @ 1136 @ 3 @ 1 4.4.1 Personnel Qualification and Training The machine may be used, maintained and repaired only by persons who are familiar with it and have been instructed about the dangers connected with it. The operator must define areas of responsibility and monitoring of personnel. -

Seite 16: Safety Instructions And Accident Prevention Regulations

Safety Pos: 12.18.5 /BA/Sicherheit/Sicherheits- und Unfallverhütungs-Vorschriften Swadro_Ladewagen_EasyCut @ 73\mod_1308298589597_78.docx @ 655493 @ 2 @ 1 Safety Instructions and Accident Prevention Regulations Please follow all generally applicable safety and accident prevention regulations in addition to the safety instructions contained in these operating instructions! The attached warning and safety signs provide important information for safe operation. -

Seite 17: Hitched Implements

Safety Parts operated by external power (e.g. hydraulically) can cause crushing and shearing injuries! Before leaving the tractor, lower the implement onto the ground, apply the parking brake, switch off the engine and remove the ignition key! Pos: 12.18.6 /BA/Sicherheit/Angehängte Geräte/Geräte angehängt @ 0\mod_1199699679381_78.docx @ 33245 @ 2 @ 1 Hitched Implements Secure implements against rolling. -

Seite 18: Pto Operation

Safety Pos: 12.18.8 /BA/Sicherheit/Zapfwellenbetrieb Traktor @ 0\mod_1199699899350_78.docx @ 33264 @ 2 @ 1 PTO operation Use only PTO shafts specified by the manufacturer! The guard tube and guard cone of the PTO shaft and the PTO guard must be attached and in good working condition (on the implement side, too)! Make sure that the required tube covers are in place for PTO shafts in transport and working position! -

Seite 19: Hydraulic System

Safety Pos: 12.18.11 /BA/Sicherheit/Hydraulikanlage @ 2\mod_1203503691986_78.docx @ 66225 @ 2 @ 1 Hydraulic system The hydraulic system is pressurised! When connecting hydraulic cylinders and motors, make sure the hydraulic hoses are connected as specified! When connecting the hydraulic hoses to the tractor hydraulics, make sure that the hydraulics of both the tractor and the implement have been depressurized! In the case of hydraulic connections between tractor and machine, the coupling sleeves and plugs should be marked to ensure a proper connection! If the connectors are... -

Seite 20: Maintenance

Replacement parts must at least comply with the technical requirements set by the manufacturer of the implements! This is guaranteed by original KRONE spare parts! Pos: 12.18.19 /BA/Sicherheit/Wartung/Wartung Zusatz Bei Gasspeicherung/Schneidwekzeuge @ 2\mod_1203504102830_78.docx @ 66265 @ @ 1... -

Seite 21: Unauthorised Conversion/Modification And Spare Parts Production

Safety Pos: 12.18.21 /BA/Sicherheit/Eigenmächtiger Umbau und Ersatzteilherstellung @ 1\mod_1201937705539_78.docx @ 55745 @ 2 @ 1 4.11 Unauthorised Conversion/Modification and Spare Parts Production Conversions or modifications of the machine are permitted only with prior consultation with the manufacturer. Original spare parts and accessories authorised by the manufacturer help to ensure safety. -

Seite 22: Commissioning

Commissioning Pos: 14.1 /Überschriften/Überschriften 1/A-E/Erstinbetriebnahme @ 0\mod_1196314201498_78.docx @ 5855 @ 1 @ 1 Commissioning Pos: 14.2 /BA/Sicherheit/Gefahrenhinweise/Gefahr - Fehlerhafter Zusammenbau @ 1\mod_1202224212591_78.docx @ 58171 @ @ 1 Danger! - Incorrect assembly Effect: Danger to life, serious injuries or serious damage to the machine. •... -

Seite 23: General

Commissioning Pos: 14.6 /BA/Inbetriebnahme/Erstinbetriebnahme/Schwader/Allgemein @ 4\mod_1213184450542_78.docx @ 87294 @ 2 @ 1 General Prior to attaching or detaching devices to or from the 3-point suspension, move the loading equipment to a position that excludes inadvertent lifting or lowering! Use extreme caution when attaching or detaching implements onto or from the tractor! In the vicinity of the 3-point linkage, there is risk of injury due to crushing and shearing points! Pos: 14.7 /Überschriften/Überschriften 2/A-E/Erstmontage @ 1\mod_1202226261982_78.docx @ 58270 @ 2 @ 1 First installation... -

Seite 24: Assembling The Support For Switching Hydraulics On The Tractor

Commissioning Pos: 14.9.6 /Überschriften/Überschriften 3/K-O/Montage des Halters der Umschalthydraulik am Traktor @ 21\mod_1239179623898_78.docx @ 230966 @ 3 @ 1 5.3.2 Assembling the support for switching hydraulics on the tractor Pos: 14.9.7 /BA/Sicherheit/Hydraulik/Gefahr - Hydraulik nicht in Kabine anschließen @ 21\mod_1239182177398_78.docx @ 231041 @ @ 1 DANGER! –... -

Seite 25: Preparations On Tractor

Commissioning Pos: 14.11.1 /Überschriften/Überschriften 2/U-Z/Vorbereitungen am Traktor @ 2\mod_1202363643678_78.docx @ 58694 @ 2 @ 1 Preparations on tractor Pos: 14.11.2 /Überschriften/Überschriften 3/U-Z/Unterlenker einstellen @ 6\mod_1214454896135_78.docx @ 94186 @ 3 @ 1 5.4.1 Adjusting the lower suspension arms Pos: 14.11.3 /BA/Inbetriebnahme/Erstinbetriebnahme/Schwader/Swadro 807_810_907/Bild_Aushubvorrichtung Traktor @ 2\mod_1202364384960_78.docx @ 58789 @ @ 1 KS-0-030 Fig. -

Seite 26: Mounting Onto The Tractor

Commissioning Pos: 14.13.1 /Überschriften/Überschriften 2/A-E/Anbau an den Traktor @ 0\mod_1199717845194_78.docx @ 34039 @ 2 @ 1 Mounting onto the Tractor Pos: 14.13.2 /BA/Inbetriebnahme/Schwader/Hinweis Maschine befindet sich in Transportstellung @ 2\mod_1202388231928_78.docx @ 59050 @ @ 1 Note The description below assumes that the swather is in transport position, following final assembly. -

Seite 27: Pto Shaft

Commissioning Pos: 14.15.1 /Überschriften/Überschriften 2/F-J/Gelenkwelle @ 0\mod_1199781879794_78.docx @ 34542 @ 2 @ 1 PTO shaft Pos: 14.15.2 /Überschriften/Überschriften 3/K-O/Längenanpassung @ 1\mod_1201687632810_78.docx @ 53589 @ 3 @ 1 5.6.1 Length adjustment Pos: 14.15.3 /BA/Inbetriebnahme/Erstinbetriebnahme/Gelenkwelle/Traktorwechsel Gelenkwellenlänge beachten @ 6\mod_1214996938591_78.docx @ 97742 @ @ 1 Caution! - Changing the tractor Effect: Damage to the machine When using the machine for the first time and whenever changing the tractor Check PTO shaft... -

Seite 28: Start-Up

Start-up Pos: 16.1 /Überschriften/Überschriften 1/F-J/Inbetriebnahme @ 0\mod_1196327075811_78.docx @ 6375 @ 1 @ 1 Start-up Pos: 16.2 /BA/Sicherheit/Gefahrenhinweise/Schwader/Gefahr - An-/ Abbau der Maschine angebaute Schwader @ 6\mod_1214455442495_78.docx @ 94229 @ @ 1 Danger! - Assembling / dismantling the machine Effect: Danger to life or serious injuries. •... -

Seite 29: Install The Pto Shaft

Start-up Pos: 16.5 /Überschriften/Überschriften 2/F-J/Gelenkwelle montieren @ 2\mod_1202398342788_78.docx @ 59253 @ 2 @ 1 Install the PTO shaft Pos: 16.6 /BA/Sicherheit/Gelenkwelle/Gefahr - Sich drehende Gelenkwelle_2 @ 0\mod_1199781692950_78.docx @ 34523 @ @ 1 Danger! - Rotating PTO shaft Effect: Danger to life or serious injuries •... - Seite 30 Start-up Pos: 16.10 /BA/Inbetriebnahme/Wender/Anbau Gelenkwelle/Bild Anbau Gelenkwelle masch-seitig KWT 8.82 bis 10.22 @ 20\mod_1239024898568_78.docx @ 227955 @ @ 1 Fig. 10 Pos: 16.11 /BA/Inbetriebnahme/Wender/Anbau Gelenkwelle/Anbau Gelenkwelle maschinenseitig KWT 8.82 bis 11.22 @ 20\mod_1239025021896_78.docx @ 228000 @ @ 1 • Switch off the engine and remove the ignition key Install the universal shaft on machine side: •...

-

Seite 31: Hydraulics

Start-up Pos: 16.15 /Überschriften/Überschriften 2/F-J/Hydraulik @ 0\mod_1199776034950_78.docx @ 34205 @ 2 @ 1 Hydraulics Pos: 16.16 /Überschriften/Überschriften 3/P-T/Spezielle Sicherheitshinweise @ 0\mod_1197301069931_78.docx @ 17662 @ 3 @ 1 6.3.1 Special Safety Instructions Pos: 16.17 /BA/Sicherheit/Hydraulik/Warnung - Anschluss der Hydraulikleitungen @ 0\mod_1199776548685_78.docx @ 34225 @ @ 1 Warning ! - Connection of the hydraulic line Effect: severe injuries due to penetration of hydraulic oil under the skin. - Seite 32 Start-up Pos: 16.22 /BA/Einstellungen/Wender/KWT 7.82/6x7; KWT 8.82/8 @ 53\mod_1289996683765_0.docx @ 508345 @ @ 1 KWT 7.82/6x7; KWT 8.82/8 Pos: 16.23 /BA/Inbetriebnahme/Wender/Hydraulikanschluss/Bild Hydraulikanschluss KWT 7.82 bis 8,82 @ 128\mod_1346316284601_78.docx @ 1149692 @ @ 1 KWT88280_1 Fig. 12 Pos: 16.24 /BA/Inbetriebnahme/Wender/Hydraulikanschluss/Hydraulikanschluss herstellen KWT 7.82 bis 11.22 @ 21\mod_1239182716241_78.docx @ 231067 @ @ 1 •...

- Seite 33 Start-up Pos: 16.29 /BA/Einstellungen/Wender/KWT 11.22/10 @ 53\mod_1289998741125_0.docx @ 508388 @ @ 1 KWT 11.22/10 Pos: 16.30 /BA/InbetriebnahmeHinweis Hydraulikaufkleber beachten (2013-06-20 07:16:16) @ 9\mod_1219997531785_78.docx @ 124879 @ @ 1 Note Connect the hydraulic lines correctly • The hydraulic hoses are identified by coloured hose clips. •...

-

Seite 34: Lighting Connection

Start-up Pos: 16.35 /BA/Inbetriebnahme/Wender/Anschluss Beleuchtung/Bild Anschluss Beleuchtung KWT 11.22_neu @ 146\mod_1360248970454_78.docx @ 1309745 @ 2 @ 1 Lighting Connection KW000014 Fig. 14 Pos: 16.36 /BA/Inbetriebnahme/Schwader/Anschluss Beleuchtung/Anschluss Beleuchtung Text SW 2000/ 700_800_900/ 807-1 bis 810-1, 850, 900# @ 36\mod_1260783798936_78.docx @ 336718 @ @ 1 The lighting system is connected via the 7-pin connection cable (1). -

Seite 35: Driving And Transport

For road transport by day or night, make certain that requirements for clearance lamps and safety measures are observed. A light mounting kit is available from your KRONE dealer. Standard attachment strips are available on the device. Pos: 18.4 /BA/---------------Seitenumbruch---------------- @ 0\mod_1196175311226_0.docx @ 4165 @ @ 1... -

Seite 36: Preparation For Transport

Driving and Transport Pos: 18.5 /Überschriften/Überschriften 2/P-T/Transportvorbereitung @ 5\mod_1213247130420_78.docx @ 87570 @ 2 @ 1 Preparation for transport Pos: 18.6 /BA/Sicherheit/Fahren und Transport/Mitfahren Straßenfahrt/Gefahr Transport Verriegelungshaken @ 20\mod_1238591323269_78.docx @ 223390 @ @ 1 DANGER! – Loss of machine during transport! Danger to life, injuries or damage to the machine. - Seite 37 Driving and Transport Pos: 18.10 /BA/Einstellungen/Wender/KWT 7.82/6x7 @ 139\mod_1354539204206_0.docx @ 1235397 @ @ 1 KWT 7.82/6x7 Pos: 18.11 /BA/Fahren und Transport/Wender/Bild Vorbereitung für den Transport KZW 7.82 @ 19\mod_1238420904818_78.docx @ 217945 @ @ 1 KW672022 Fig. 16 Pos: 18.12 /BA/Fahren und Transport/Wender/Vorbereitung für den Transport KZW 7.82 @ 139\mod_1354531676971_78.docx @ 1235254 @ @ 1 For reducing the transport width (<...

-

Seite 38: Mounting The Safety Chain To The Tractor

Driving and Transport Pos: 18.17 /Überschriften/Überschriften 2/P-T/Sicherheitskette an den Traktor montieren @ 147\mod_1361183080699_78.docx @ 1319805 @ 2 @ 1 Mounting the Safety Chain to the Tractor Pos: 18.18 /Beipacks/Allgemein/Sicherheitskette 89kN/Sicherheitskette am Traktor montieren Mäher,Schwader,Wender Bild @ 150\mod_1362048508388_78.docx @ 1343347 @ @ 1 ZBBP0899_1 Fig. -

Seite 39: Operation

Compare the applicable RM torque value on the overload coupling with the value specified in the following table. If these values do not match, please contact your Krone dealer. Pos: 20.2.6 /BA/Bedienung /Wender/Überlastsicherung/Überlastsicherung Drehmoment-Tabelle KWT 8.82 bis 11.22 @ 20\mod_1239083658058_78.docx @ 228256 @ @ 1... -

Seite 40: From Transport Into Working Position

Pos: 20.6 /BA/Bedienung /Wender/KWT 7.82 und 8.82 @ 20\mod_1239084243730_78.docx @ 228411 @ @ 1 KWT 7.82/6x7, KWT 8.82/8 Pos: 20.7 /BA/Bedienung /Wender/Bild Absperrhahn KWT 7.82 bis 8.82 @ 21\mod_1239084466636_78.docx @ 228436 @ @ 1 KWT8828015 Fig. - Seite 41 Operation Pos: 20.10 /BA/Bedienung /Wender/Wender absenken Grundeinstellung KW 4.62 bis 8.82 @ 139\mod_1354532708578_78.docx @ 1235373 @ @ 1 KW6722021 Fig. 22 • Swivel impeller (2) of the second rotor from the inside into working position. • Secure with bolt (1) and cotter pin. Note Mind the position of the single wheels (refer to chapter “Spreading Angle Setting of the Rotors”) when swivelling into working position.

- Seite 42 Operation Pos: 20.16 /BA/Bedienung /Wender/Bild Wender absenken Verriegelung entlasten KW 4.62 bis 8.82 @ 19\mod_1238421463021_78.docx @ 218106 @ @ 1 KW672003 Fig. 24 Pos: 20.17 /BA/Bedienung /Wender/Wender absenken Verriegelung entlasten KW 4.62 bis 8.82 @ 14\mod_1227190545368_78.docx @ 169133 @ @ 1 •...

-

Seite 43: Working Depth Of The Rotor Tines

Operation Pos: 20.20 /BA/Bedienung /Wender/Zinken/Einstellen der Arbeitstiefe Kreiselzinken KWT 7.82 bis 11.22 @ 21\mod_1239087206965_78.docx @ 228580 @ 2 @ 1 Working depth of the rotor tines KWT8828008 Fig. 25 Adjustment of working depth of the rotor tines is done on the lower link (1). Bring the machine into working position on a level surface. -

Seite 44: Using The Machine For Work

Operation Pos: 20.23 /Überschriften/Überschriften 2/A-E/Arbeitseinsatz @ 5\mod_1213258631763_78.docx @ 87907 @ 2 @ 1 Using the Machine for Work Pos: 20.24 /BA/Sicherheit/Gefahrenhinweise/Schwader/Gefahr Arbeitseinsatz angebaute Geräte @ 5\mod_1213261151763_78.docx @ 87927 @ @ 1 Danger! - Using the Machine for Work Effect: Danger to life or serious injuries. •... - Seite 45 Operation Pos: 20.28 /BA/Bedienung /Wender/Bild Schwadbildung Wender @ 31\mod_1252311403211_78.docx @ 303436 @ @ 1 KW999001 Fig. 26 Pos: 20.29 /BA/Bedienung /Wender/Einstellung gleichmäßiger Schwad @ 31\mod_1252308723586_78.docx @ 303230 @ @ 1 Target setting for quick drying An even spread pattern is the target of such a work process with the tedder. In the process the forage is supposed to lie in an even carpet behind the tedder.

-

Seite 46: Exchanging The Wheels

Operation Pos: 20.31.1 /Überschriften/Überschriften 3/P-T/Räder tauschen @ 33\mod_1254896471908_78.docx @ 320605 @ 3 @ 1 8.4.1 Exchanging the wheels Pos: 20.31.2 /BA/Bedienung /Wender/Bild Rädertausch Wender @ 33\mod_1254895663815_78.docx @ 320506 @ @ 1 KW8828200 Fig. 27 Pos: 20.31.3 /BA/Bedienung /Wender/Räder tauschen @ 33\mod_1254896126018_78.docx @ 320580 @ @ 1 In case forage deposits on the wheel arms, the inner wheels should be exchanged according to the figure. -

Seite 47: Switching From Working Position To Transport Position

Secure the tractor against rolling. Pos: 20.37 /BA/Bedienung /Wender/KWT 7.82 und 8.82 @ 20\mod_1239084243730_78.docx @ 228411 @ @ 1 KWT 7.82/6x7, KWT 8.82/8 Pos: 20.38 /BA/Bedienung /Wender/Bild Absperrhahn KWT 7.82 bis 8.82 @ 21\mod_1239084466636_78.docx @ 228436 @ @ 1 KWT8828015 Fig. - Seite 48 Operation Pos: 20.45 /BA/Sicherheit/Fahren und Transport/Mitfahren Straßenfahrt/Gefahr Straßenfahrt, Mitfahren Swadro zusatz SW 700_800_900 @ 134\mod_1350554825014_78.docx @ 1188912 @ @ 1 WARNING! There is a danger to life if the transport interlock is not correctly engaged. • Perform a visual inspection to ensure the locks (1) have engaged correctly. Pos: 20.46 /BA/Bedienung /Wender/Bild Umschalthahn zu KWT 7.82 bis 11.22 @ 21\mod_1239171580866_78.docx @ 230450 @ @ 1 KWT8828015 Fig.

-

Seite 49: Parking

Operation Pos: 20.49 /Überschriften/Überschriften 2/A-E/Abstellen @ 0\mod_1199801980622_78.docx @ 35320 @ 2 @ 1 Parking Pos: 20.50 /BA/Sicherheit/Gefahrenhinweise/Schwader/Gefahr - Maschine abstellen angebaute Geräte ohne Hydraulik @ 6\mod_1214458085073_78.docx @ 94272 @ @ 1 DANGER! – Unexpected movements of the machine Effect: Danger to life, serious injuries •... - Seite 50 Operation Pos: 20.54 /BA/Sicherheit/Gefahrenhinweise/Schwader/Gefahr - Maschine abstellen gezogene Geräte @ 2\mod_1202726300830_78.docx @ 60434 @ @ 1 Danger! – Unexpected movements of the machine! Danger to life, serious injuries • No persons may remain in the danger zone. • Set the machine down a solid surface. •...

-

Seite 51: Settings

Settings Pos: 22.1 /Überschriften/Überschriften 1/A-E/Einstellungen @ 0\mod_1199868783862_78.docx @ 36141 @ 1 @ 1 Settings Pos: 22.2 /BA/Sicherheit/Gefahrenhinweise/WenderGefahr - Einstellungen am Wender (2013-04-23 14:01:46) @ 16\mod_1235651505877_78.docx @ 200148 @ @ 1 DANGER! - Settings on the machine! Danger to life or serious injuries. •... - Seite 52 Settings Pos: 22.4 /BA/Einstellungen/Wender/KWT 7.82/6x7; KWT 8.82/8 @ 53\mod_1289996683765_0.docx @ 508345 @ @ 1 KWT 7.82/6x7; KWT 8.82/8 Pos: 22.5 /BA/Bedienung /Wender/Bild Absperrhahn KWT 7.82 bis 8.82 @ 21\mod_1239084466636_78.docx @ 228436 @ @ 1 KWT8828015 Fig. 34 Pos: 22.6 /BA/Sicherheit/Gefahrenhinweise/Wender/Gefahr - Absperrhahn geschlossen @ 21\mod_1239095981590_78.docx @ 229080 @ @ 1 DANGER! - Settings on the machine! Danger to life or serious injuries.

- Seite 53 Settings Pos: 22.11 /BA/Einstellungen/Wender/Bild Grundlage Streuwinkeleinstellung @ 19\mod_1238422787490_78.docx @ 218400 @ @ 1 KW672004 Fig. 36 Pos: 22.12 /BA/Einstellungen/Wender/Hinweis Einstellung Streuwinkel @ 16\mod_1235652148877_78.docx @ 200328 @ @ 1 Note • The setting of the spreading angle of the rotor tines must be adapted to the conditions of the surface and the material •...

- Seite 54 Settings Pos: 22.16 /BA/Einstellungen/Wender/Grafik Streuwinkeleinstellung @ 16\mod_1235652430033_78.docx @ 200403 @ @ 1 KW-0-019 Fig. 37 Pos: 22.17 /BA/Einstellungen/Wender/Streuwinkeleinstellung @ 17\mod_1235654610111_78.docx @ 200479 @ @ 1 Setting: Remove cotter pin (1) and pull out bolt (2) Bring wheel support (3) into chosen position between position I and position II Push bolt in again and secure it with the cotter pin Bolt in direction I = steep spreading angle...

-

Seite 55: Spread Limiter

Settings Pos: 22.22.1 /Überschriften/Überschriften 2/F-J/Grenzstreueinrichtung @ 19\mod_1238481225085_78.docx @ 218900 @ 2 @ 1 Spread limiter Pos: 22.22.2 /BA/Einstellungen/Wender/Bild Grenzstreueinrichtung KWT 7.82 bis 11.22 @ 21\mod_1239098908121_78.docx @ 229265 @ @ 1 KWT8828009_1 Fig. 39 Pos: 22.22.3 /BA/Einstellungen/Wender/Grenzstreueinrichtung KWT 8.82 bis 11.22 @ 21\mod_1239099214965_78.docx @ 229315 @ @ 1 Setting the spread limiter: Set the hydraulic switching valve (2) to position “b”... -

Seite 56: Setting Of Tines

Settings Pos: 22.24 /BA/Einstellungen/Wender/Zinkeneinstellung @ 19\mod_1238079129257_78.docx @ 214915 @ 2 @ 1 Setting of tines KW-1-058 Fig. 40 The tines (3) must be aligned vertically to the surface. The setting of the tines can be changed by turning the eccentrics. For setting: •... -

Seite 57: Adjusting The Bar Hinge Point Inside To The Intermediate Bar

9.3.1 Adjusting the bar hinge point inside to the intermediate bar Pos: 22.25.4 /BA/Einstellungen/Wender/Bild Scharnierstelle einstellen KWT 7.82 und 11.22 @ 21\mod_1239107685027_78.docx @ 229735 @ @ 1 KWT 7.82/6x7 /KWT 11.22/10 KW672033 Fig. 42 Pos: 22.25.5 /BA/Einstellungen/Wender/Hinweis Gestänge entspannen @ 20\mod_1238657292851_78.docx @ 224115 @ @ 1 Note •... - Seite 58 Bring the machine into the transport position • Close the shut-off valve (3) on the running gear (only on KWT 7.82/6x7; KWT 8.82/8) Pos: 22.25.11 /BA/Einstellungen/Wender/Achtung Gestänge entspannen @ 20\mod_1238657418070_78.docx @ 224160 @ @ 1 CAUTION! - distance dimension "X" undershot Effect: Material damages •...

- Seite 59 Settings Pos: 22.25.13 /BA/Einstellungen/Wender/Bild Scharnierstelle einstellen KWT 8.82 @ 29\mod_1251205230794_78.docx @ 281680 @ @ 1 KWT 8.82/8 KW672027 Fig. 44 KW672070 Fig. 45 Pos: 22.25.14 /BA/Einstellungen/Wender/Hinweis Gestänge entspannen @ 20\mod_1238657292851_78.docx @ 224115 @ @ 1 Note • Shorten linkage (2) => distance dimension "X" becomes greater => pendulum area of the bars is reduced •...

-

Seite 60: Setting The Linking Rod

Settings Pos: 22.25.18 /Überschriften/Überschriften 3/A-EAnlenkgestänge einstellen @ 19\mod_1238410611521_78.docx @ 216345 @ 3 @ 1 9.3.2 Setting the linking rod Pos: 22.25.19 /BA/Einstellungen/Wender/Bild Anlenkgestänge Kw 4.62 bis 8.82 @ 19\mod_1238484265069_78.docx @ 219024 @ @ 1 KW672100 Fig. 46 Pos: 22.25.20 /BA/Einstellungen/Wender/Aushubzylinder einstellen KWT 8.82/8 @ 68\mod_1304935323914_78.docx @ 629345 @ @ 1 •... -

Seite 61: Setting The Tension Spring On The Linking Rod

Settings Pos: 22.25.24 /Überschriften/Überschriften 3/A-E/Einstellung der Zugfeder am Anlenkgestänge @ 19\mod_1238412523412_78.docx @ 216841 @ 3 @ 1 9.3.3 Setting the tension spring on the linking rod Pos: 22.25.25 /BA/Bedienung /Wender/Nur bei KWT 8.82 @ 36\mod_1260428605856_78.docx @ 336536 @ @ 1 Only on KWT 8.82 Pos: 22.25.26 /BA/Einstellungen/Wender/Bild Zugfeder am Anlenkgestänge KW 4.62 bis 8.82 @ 55\mod_1294729071265_78.docx @ 531225 @ @ 1 Detail... -

Seite 62: Setting The Transport Interlocks

Settings Pos: 22.27 /Überschriften/Überschriften 2/A-E/Einstellung Transportverriegelungen @ 156\mod_1363777041605_78.docx @ 1376522 @ 2 @ 1 Setting the Transport Interlocks Pos: 22.28 /BA/Einstellungen/Wender/Grafik Verriegelungshaken KW 4.62 bis 8.82 @ 27\mod_1247119085261_78.docx @ 269696 @ @ 1 KW672031 Fig. 49 Pos: 22.29 /BA/Einstellungen/Wender/Verriegelungshaken einstellen @ 27\mod_1247119130324_78.docx @ 269721 @ @ 1 Note The setting of the locking hook (1) must be checked before the beginning of the season. -

Seite 63: Maintenance

Effect: Danger to life, serious injuries or loss of warranty claims as well as exclusion of liability • Use only authentic KRONE spare parts and accessories authorised by the manufacturer. The use of spare parts, accessories or additional equipment not manufactured, tested or approved by KRONE will exclude any liability for consequential damage. -

Seite 64: Special Tightening Torques Ma (Nm)

Maintenance Pos: 24.8 /Überschriften/Überschriften 2/A-E/Abweichende Anzugsmoment zur Tabelle @ 45\mod_1276766465640_78.docx @ 408816 @ 2 @ 1 10.3 Special tightening torques M (Nm) Pos: 24.9 /BA/Wartung/Drehmomente / Anzugsmomente/Hinweis Anzugsmomente allgemein @ 16\mod_1235563920740_78.docx @ 198846 @ @ 1 Note The tightening torques listed in the chapter on maintenance under "Tightening Torques" and "Tightening Torques (Countersunk Screws)"... -

Seite 65: Tightening Torques

Maintenance Pos: 24.14 /Überschriften/Überschriften 2/A-E/Anzugsdrehmomente @ 45\mod_1277103093968_78.docx @ 410970 @ 2 @ 1 10.4 Tightening Torques Pos: 24.15 /BA/Wartung/Drehmomente / Anzugsmomente/Drehmomente @ 45\mod_1277102920578_78.docx @ 410945 @ @ 1 A = Thread size The tightening torque M is stated in Nm (The stability class can be seen on the head of the (unless otherwise indicated). -

Seite 66: Tightening Torques (Countersunk Screws)

Maintenance Pos: 24.18 /Überschriften/Überschriften 2/A-E/Anzugsdrehmomente über Innensechskant @ 45\mod_1277106415765_78.docx @ 411230 @ 2 @ 1 10.5 Tightening Torques (Countersunk Screws) Pos: 24.19 /BA/Wartung/Drehmomente / Anzugsmomente/Drehmomente über Innensechskant @ 45\mod_1277106232328_78.docx @ 411205 @ @ 1 A = Thread size The tightening torque M is stated in Nm (The stability class can be seen on the head of the (unless otherwise indicated). -

Seite 67: Maintenance Hydraulics

Maintenance Pos: 24.22 /Überschriften/Überschriften 2/U-Z/Wartung Hydraulik @ 21\mod_1239189439538_78.docx @ 231282 @ 2 @ 1 10.6 Maintenance hydraulics Pos: 24.23 /BA/Sicherheit/Gefahrenhinweise/Gefahr - Hydraulikspeicher @ 21\mod_1239189699820_78.docx @ 231325 @ @ 1 DANGER! – Hydraulic liquids squirt under high pressure! Effect: Serious injuries •... -

Seite 68: Hydraulic Circuit Diagram

Pos: 24.28 /Überschriften/Überschriften 3/F-J/Hydraulikschaltplan @ 21\mod_1239190146695_78.docx @ 231350 @ 3 @ 1 10.6.2 Hydraulic circuit diagram Pos: 24.29 /BA/Wartung/Wender/Hydraulik/Hydraulikschaltpläne KWT 7.82 bis 11.22 @ 128\mod_1346318488536_78.docx @ 1149840 @ @ 1 KWT 7.82/6x7 KWT 8.82/8 KWT8828022 Fig. 53: Hydraulic cylinder of running gear... - Seite 69 Maintenance Fig. 54: Hydraulic cylinder of running gear Hydraulic cylinder of external rotor Hydraulic cylinder spread limiter Pos: 24.30 /BA/---------------Seitenumbruch---------------- @ 0\mod_1196175311226_0.docx @ 4165 @ @ 1...

-

Seite 70: Tyres

If tyres are not correctly fitted, it could explode when pumped up. This can cause serious injury. If you do not have sufficient experience of fitting tyres, have tyres fitted by the KRONE dealer or a qualified tyre specialist. •... -

Seite 71: Checking And Maintaining Tyres

Maintenance Pos: 24.31.4 /Überschriften/Überschriften 3/P-T/Reifen prüfen und pflegen @ 0\mod_1197358037214_78.docx @ 18094 @ 3 @ 1 10.7.1 Checking and maintaining tyres Pos: 24.31.5 /BA/Wartung/Reifen/Reihenfolge Bild 6-Loch @ 4\mod_1213086131413_78.docx @ 86197 @ @ 1 KS-0-034 Fig. 55 Pos: 24.31.6 /BA/Wartung/Reifen/Wender/Reihenfolge Reifenmontage Wender @ 21\mod_1239192011538_78.docx @ 231661 @ @ 1 When loosening and tightening the wheel nuts, observe the order indicated in the illustration. -

Seite 72: Maintenance - Lubrication Chart

Maintenance – lubrication chart Pos: 24.33.1 /Überschriften/Überschriften 1/U-Z/Wartung - Schmierplan @ 0\mod_1197359304198_78.docx @ 18232 @ 1 @ 1 Maintenance – lubrication chart Pos: 24.33.2 /Überschriften/Überschriften 2/P-T/Spezielle Sicherheitshinweise @ 0\mod_1196660495760_78.docx @ 9134 @ 2 @ 1 11.1 Special Safety Instructions Pos: 24.33.3 /BA/Sicherheit/Gefahrenhinweise/Ladewagen/Gefahr Wartung allgemein @ 0\mod_1199884069862_78.docx @ 36704 @ @ 1 Danger! - When performing repair, maintenance or cleaning work on the machine, or in the case of technical intervention, drive elements may start moving. -

Seite 73: Maintenance - Lubrication Chart

Maintenance – lubrication chart Pos: 24.33.8 /Überschriften/Überschriften 2/U-Z/Schmierplan @ 21\mod_1239257921942_78.docx @ 231886 @ 2 @ 1 Lubrication chart Pos: 24.33.9 /BA/Wartung/Hinweis aus Gründen der Übersicht @ 2\mod_1202799283498_78.docx @ 61453 @ @ 1 Note To make the illustration easier to read, the greasing points have only been shown on one side of the machine. -

Seite 74: Maintenance - Gearbox

Maintenance - Gearbox Pos: 24.35.1 /Überschriften/Überschriften 1/U-Z/Wartung - Getriebe @ 2\mod_1203058202823_78.docx @ 64495 @ 1 @ 1 Maintenance - Gearbox Pos: 24.35.2 /Überschriften/Überschriften 2/F-J/Füllmengen und Schmiermittelbezeichnungen der Getriebe @ 0\mod_1196951094046_78.docx @ 15335 @ 2 @ 1 12.1 Filling Quantities and Lubrication Designations for Gearboxes Pos: 24.35.3 /BA/Wartung/Tabellen/Wender/Tabelle Füllmengen KW 4.62 bis 8.82 @ 30\mod_1251376165730_78.docx @ 286710 @ @ 1 Filling Filtered oils... -

Seite 75: Special Equipment

Special equipment Pos: 26.1 /Überschriften/Überschriften 1/P-T/Sonderausstattung @ 2\mod_1202808469779_78.docx @ 61649 @ 1 @ 1 Special equipment Pos: 26.2 /BA/Sicherheit/Gefahrenhinweise/Einstellarbeiten / Einstellungen/Gefahr - Einstellarbeiten gezogene Maschinen @ 0\mod_1199717011038_78.docx @ 33980 @ @ 1 Danger! - Unexpected movements of the machine Effect: Danger to life or serious injuries. •... -

Seite 76: Spare Wheel With Support

Special equipment Pos: 26.5 /Überschriften/Überschriften 2/A-E/Ersatzrad mit Halter @ 21\mod_1239262899489_78.docx @ 232009 @ 2 @ 1 13.2 Spare wheel with support Pos: 26.6 /BA/Sonderausstatung/Wender/Bild Ersatzrad @ 21\mod_1239262985473_78.docx @ 232033 @ @ 1 KWT8828046_2 Fig. 59 Pos: 26.7 /BA/Sonderausstatung/Wender/Ersatzrad mit Halter @ 21\mod_1239263160395_78.docx @ 232057 @ @ 1 The spare wheel (1) can be installed at different points on the machine with the supplied support. -

Seite 77: Jockey Wheel Front

Special equipment Pos: 26.9.1 /Überschriften/Überschriften 2/U-Z/Tastrad @ 20\mod_1238658857179_78.docx @ 224265 @ 2 @ 1 13.3 Jockey wheel front Pos: 26.9.2 /BA/Sonderausstatung/Wender/Bild Tastrad KWT 7.82 bis 11.22 @ 22\mod_1239777431070_78.docx @ 233011 @ @ 1 KWT8828040_2 Fig. 60 Pos: 26.9.3 /BA/Sonderausstatung/Wender/Tastrad KW 7.82 bis 11.22 @ 22\mod_1239782272320_78.docx @ 233146 @ @ 1 Assemble the jockey wheel (3) on the right in the direction of travel as follows: •... -

Seite 78: Anti-Wrap Guard Plate Tyres

Special equipment Pos: 26.11 /Überschriften/Überschriften 2/U-Z/Wickelschutzblech Bereifung @ 19\mod_1238072897195_78.docx @ 214066 @ 2 @ 1 13.4 Anti-wrap guard plate tyres Pos: 26.12 /BA/Sonderausstatung/Wender/Bild Wickelschutzblech KW 4.62 bis 8.82 @ 19\mod_1238074068460_78.docx @ 214308 @ @ 1 KZW46202 Fig. 61 Pos: 26.13 /BA/Sonderausstatung/Wender/Wickelschutzblech montieren @ 19\mod_1238074858304_78.docx @ 214476 @ @ 1 Installing the anti-wrap guard (1) : •... -

Seite 79: Placing In Storage

Placing in Storage Pos: 28.1 /Überschriften/Überschriften 1/A-E/Einlagerung @ 0\mod_1197385459120_78.docx @ 19966 @ @ 1 Placing in Storage Pos: 28.2 /Überschriften/Überschriften 2/P-T/Spezielle Sicherheitshinweise @ 0\mod_1196660495760_78.docx @ 9134 @ @ 1 14.1 Special Safety Instructions Pos: 28.3 /BA/Sicherheit/Gefahrenhinweise/Ladewagen/Gefahr Wartung allgemein @ 0\mod_1199884069862_78.docx @ 36704 @ @ 1 Danger! - When performing repair, maintenance or cleaning work on the machine, or in the case of technical intervention, drive elements may start moving. -

Seite 80: At The End Of The Harvest Season

Perform the necessary repair tasks during the time immediately after the harvest season. Draw up a list of all replacement parts you will need. This will make it easier for your KRONE dealer to process your orders and you will be certain that your machine will be ready for use at the beginning of the next season. -

Seite 81: Before The Start Of The New Season

Pos: 28.8 /Überschriften/Überschriften 2/U-Z/Vor Beginn der neuen Saison @ 0\mod_1197386024448_78.docx @ 20081 @ @ 1 14.3 Before the Start of the New Season Pos: 28.9 /Überschriften/Überschriften 2/P-T/Spezielle Sicherheitshinweise @ 0\mod_1196660495760_78.docx @ 9134 @ 2 @ 1 14.4 Special Safety Instructions Pos: 28.10 /BA/Sicherheit/Gefahrenhinweise/Ladewagen/Gefahr Wartung allgemein @ 0\mod_1199884069862_78.docx @ 36704 @ @ 1 Danger! - When performing repair, maintenance or cleaning work on the machine, or in the case of technical intervention, drive elements may start moving. -

Seite 82: Index

Index Adjusting the bar hinge point inside to the Jockey wheel front ..........77 intermediate bar ..........57 Adjusting the lower suspension arms ....25 Lubrication chart ..........73 Affixing the Adhesive Safety and Information Labels ..............11 Anti-wrap guard plate tyres ......... 78 Maintenance .......... - Seite 83 Spread limiter ............55 Travelling on an incline ........46 Start-up ............... 28 Tyres ............19, 70 Switching from working position to transport position ............... 47 Unauthorised Conversion/Modification and Spare Parts Production ..........21 Target setting for quick drying ......45 Using the Machine for Work ......

- Seite 84 . . konsequent, kompetent Maschinenfabrik Bernard Krone GmbH Heinrich-Krone-Straße 10, D-48480 Spelle Postfach 11 63, D-48478 Spelle Phone +49 (0) 59 77/935-0 +49 (0) 59 77/935-339 Internet: http://www.krone.de eMail: info.ldm@krone.de...