Werbung

Werbung

Inhaltsverzeichnis

Inhaltszusammenfassung für PIAB COMPACT10E

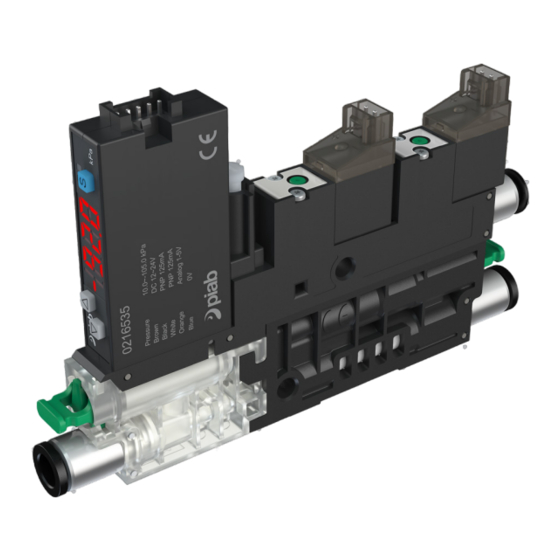

- Seite 1 Installation Manual COMPACT10E Air-driven ejector pump COMPACT10E...

- Seite 2 ► (IT) Questo è un manuale di installazione. La lingua originale del presente manuale è l’inglese. Per un manuale completo del prodotto, in inglese e in altre lingue, visitare il sito www.piab. com e selezionare la lingua desiderata. ►...

- Seite 3 안전 지침 (FR) CONSIGNES DE SÉCURITÉ (KR) WARNING! Do not install or operate your COMPACT10E if it is damaged during transport, handling or use. Damage may result in bursting and cause injury or property damage. Do not use electrical cables longer than 30 m (98 ft), otherwise damage to equipment and application failure can result.

- Seite 4 (GB/US) The product COMPACT10E is intended to be incorporated into machinery or to be assembled with other machinery to constitute machinery covered by Directive 2006/42/EC, as amended. It is not allowed to put the product into service until the machinery into which it is to be incorporated or of which it is to be a component has been found and declared to be in conformity with the provision of Directive 2006/42/EC and with national implementing legislation, i.e.

- Seite 5 (FR) Le produit COMPACT10E est destiné à être intégré à une machine ou à être assemblé avec une autre machine, afin de constituer une machine relevant de la directive 2006/42/CE, telle que modifiée. La mise en service du produit n’est pas autorisée tant que la machine dans laquelle il doit être...

- Seite 6 (SE) COMPACT10E är avsedd att införlivas i maskiner eller monteras med annan utrustning för att utgöra maskiner som omfattas av direktiv 2006/42/EG, i dess ändrade lydelse. Det är inte tillåtet att använda produkten förrän den utrustning som den ska införlivas i eller utgöra en del av uppfyller kraven i direktiv 2006/42/EG och nationell lagstiftning i sin helhet, dvs.

- Seite 7 (PL) Produkt COMPACT10E jest przeznaczony do integracji z maszyną lub montażu z inną maszyną w celu stworzenia nowej maszyny spełniającej wymagania dyrektywy 2006/42/WE z poprawkami. Nie jest dozwolone wprowadzenie maszyny do eksploatacji, jeśli maszyna objętą...

- Seite 8 Режимы продувки или отведение отработанного объема эжектора запрещено использовать в целях повышения давления в герметичных емкостях, таких как цилиндры, баки, бочки и т. д. (JP) 本 製品 は、 改訂指令 の対象となる機械を構成するために、 機械に組み込まれるか、 他の機械と組み立てられ COMPACT10E 2006/42/EC ることを意図しています。本製品は、統合されるかコンポーネントとなる機械が指令 の規定および国内の実 施法に準拠してい 2006/42/EC ることが判明し、宣言されるまで、 すなわち、 この宣言で言及される機械を含む全体として、 使 用することはできません。...

-

Seite 9: Channels In A Manifold Mount

MOUNTING COMPACT10E can be installed as a single unit/channel mounted sideways, or as multiple (2 to 8) units in a stack mounted upright. 1 CHANNEL 2-8 CHANNELS IN A MANIFOLD MOUNT Stack Unit 2 ch 3 ch 4 ch 5 ch... - Seite 10 OVERVIEWS AND CONNECTIONS OVERVIEW 1 CHANNEL Position Description Note Compressed air connection Vacuum connection Central exhaust connection Exhaust is either C1 or C2 Exhaust C1 or C2 Only when no central exhaust D1+D2 Silencer (integrated) and plug connection E1+E2 Vacuum filter and holder F1+F2 COAX®...

- Seite 11 CONNECTIONS 1 CHANNEL Position Description Size Compressed air Ø4 / Ø6 Vacuum Ø4 / Ø6 Exhaust Central exhaust Ø6 Vacuum sensing port Vacuum sensor...

- Seite 12 OVERVIEW 2-8 CHANNELS Position Description Note Left gable Right gable One back gable per pump unit in Back gable a stack. Central exhaust Mounted on left gable. B1 or B2. Central silencer Mounted on left gable. B1 or B2.

- Seite 13 CONNECTIONS 2-8 CHANNELS Position Description Size Central compressed air Ø6 / Ø8 Vacuum Ø4 / Ø6 Central silencer Central exhaust Ø12 Vacuum sensing port Vacuum sensor...

-

Seite 14: Pneumatic Installation

INSTALLATION Before installing the COMPACT10E unit, check the product and attachments (such as hoses, hose clamps, clips etc) for damages. Replace any damaged parts with new parts. Wear safety glasses and ear protection when installing the product. Using compressed air pressure and/or electrical voltage outside specification can cause equipment damage and/or application failure. - Seite 15 • Clean room installation COMPACT10E is suitable for use in cleanroom environments. As the valves close the exhaust air is recycled back to the valve outlet port. For clean room installations of a stack of pumps, it is recommended to attach a Ø12mm quick connection to the central exhaust, located on the left gable.

-

Seite 16: Electrical Installation

ELECTRICAL INSTALLATION Do not use electrical cables longer than 30 m (98 ft), otherwise damage to equipment and application failure can result. Turn power off before connecting the electrical wires. Miswiring may result in short circuits that can cause damage to the ejector and/or cause it to malfunction. Vacuum valve and blow-off valve The vacuum valve and the blow-off valve each have a 2 pin electrical connection, marked with their polarities + and -. - Seite 17 Vacuum sensor The vacuum sensor switch has a 5 pin electrical connection and comes with an electrical cable. The cable wires are connected to the pins of the sensor according to the table below. The vacuum sensor is optional and comes in two different versions, PNP and NPN open collector with 1 analog and 2 digital output signals.

-

Seite 18: Technical Data

TECHNICAL DATA Pneumatic technical information (per channel) Description Unit COAX ® Xi2.5-2 Ti05-2 Feed pressure, pump at optimal. MPa [psi] 0.52 [75.4] 0.50 [72.5] Nozzle pressure at optimal pump feed MPa [psi] 0.50 [72.5] 0.40 [58.0] pressure Maximum feed pressure MPa [psi] 0.70 [101.5] Max vacuum at opt. - Seite 19 Valve module Function vacuum valve Normally closed (NC) Function blow-off valve Normally closed (NC) Supply voltage 24 V DC ±10% Power 3.5 W (15 ms), 0.3 W PWM holding Response time ≤ 3 ms Electrical connection Supplied cables 300mm, Red (+) Black (-) Air consumption blow-off/release 0-1.01 Nl/s at 6 bar [0-2.14 scfm at 87 psi] Manual override...

- Seite 20 Brazil China Lagny sur Marne Täby (HQ) Sao Paulo Shanghai +33 (0)16-430 82 67 +46 (0)8-630 25 00 +55 (0)11-449 290 50 +86 21 5237 6545 info-france@piab.com info-sweden@piab.com info-brasil@piab.com info-china@piab.com Mölndal Germany Canada India Ergonomic Handling +46 (0)31-67 01 00...