Inhaltsverzeichnis

Werbung

Werbung

Inhaltsverzeichnis

Inhaltszusammenfassung für ZF 280-1A

- Seite 2 This document is protected by copyright. Complete or partial reproduction or dissemination of this document is prohibited without the consent of ZF Friedrichshafen AG. Infringements lead to civil and criminal prosecution. This document is a translation of the Italian original.

- Seite 3 GENERAL CONTENTS Introduction section 1 Technical data section 2 Emergency control section 3 Installation section 4 Maintenance section 5 Troubleshooting section6 Service centres section 7 INDICE GENERALE / INDEX GENERAL ÌNDICE GENERAL / INHALTSVERZEICHNIS Introduzione / Introduction sezione/section Introducción / Vorwort sección/abschnitt 1 Dati tecnici / Données techniques sezione/section...

- Seite 4 ATTENTION ZF PADOVA s.r.l. is not liable for any damage or loss caused by the incorrect installation, improper use or lack of maintenance of the equipment. ZF PADOVA S.r.l. is not responsible for any torsional vibration caused by the incorrect interaction between engine, shaft and propeller.

-

Seite 5: Operation

The following symbols are used to highlight important information on technical reliability and safety: This symbol denotes a procedure that could result in physical injury to the operator or to other persons in the vicinity if not followed correctly. The warning symbol denotes procedures which, if not carried out or only partially carried out, may result in damage to the marine gearbox, engine or connected equipment. - Seite 6 Counter engine rotation The output shaft [2] connected to the propeller shaft rotates in the opposite direction to the input shaft [1]. ZF 280-1 ZF 280-1A Fig. 4 ZF 280 IV Fig. 5 E.R.= direction of rotation same as direction of rotation of engine C.E.R.= direction of rotation opposite to direction of rotation of engine...

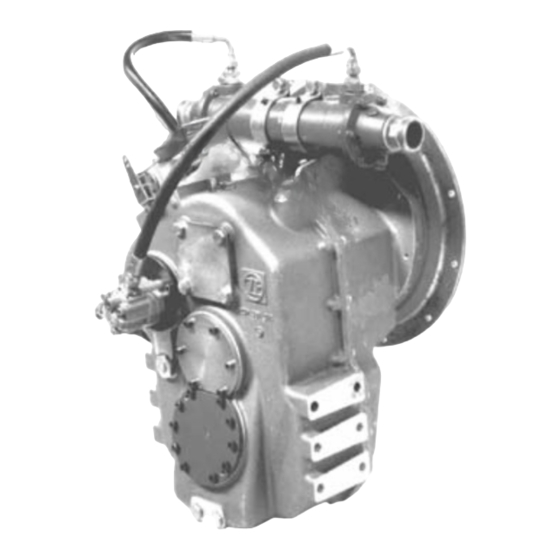

- Seite 7 The gearbox can be supplied with or without optionals (oil cooler, flexible coupling, brackets, trolling valve). Gearboxes are supplied without oil. ZF 280 fam. - ZF 280A fam. Fig.6 Tab. 1 POS. POS. DESCRIPTION DESCRIPTION Breather PTO cover Oil cooler...

- Seite 8 MECHANICAL TROLLING VALVE (M.T.V.) The trolling valve is a device that allows the number of propeller revolutions to be changed independen- tly of the engine running speed. The M.T.V. is usually applied in the following circumstances: 1) when the boat speed is too high, even though the engine is idling. 2) when the rotation speed of the PTO must be greater than the propeller rotation speed.

-

Seite 9: Technical Data

(l/min at 1000rpm) (bar) temperature (°C) ZF 280-1 4 ÷ 5 23 ÷ 24 40 ÷ 80 ZF 280-1A 4 ÷ 5 23 ÷ 24 40 ÷ 80 ZF 280 IV 5 ÷ 6 23 ÷ 24 40 ÷ 80 Notes * ) gearbox without optionals;... - Seite 10 OIL TYPES Use the following oils (see norm ZF-TLM 04 edition02/2009): Lubricant class 04A Monograde engine oil (API CD/CE/CF-4/CF/CG-4/CH-4/CI-4/SF/SG/SH/SJ/SL or ACEA categories A/B/E) Viscosity grade: SAE 30, also SAE 40 in hot countries or when oil sump temperatures are above +80°C Note: 1.

- Seite 11 Lubricant class 04C Multigrade engine oil Viscosity grades: SAE 5W-40 / 10W-40 / 15W-40 Manufacturer (04C) Trade name (04C) ADDINOL LUBE OIL GMBH, LEUNA/D ADDINOL SUPER STAR MX 1547 SAE 15W-40 AGIP SCHMIERTECHNIK GMBH, WÜRZBURG/D AGIP BLITUM T SAE 15W-40 AGIP SCHMIERTECHNIK GMBH, WÜRZBURG/D AUTOL VALVE SHP SAE 15W-40 AVIA MINERALÖL-AG, MÜNCHEN/D...

-

Seite 12: Emergency Control

EMERGENCY CONTROL ELECTRICAL SYSTEM BREAKDOWN If a breakdown occurs in the electrical system or the solenoid valve solenoids, the clutches can be engaged manually with a mechanical system. To operate this system, remove the cap [2] (Fig. 10), press the button [3] (Fig. 11) and turn anti-clockwise. Fig.11 Fig.10 A= valve closed (normal position) -

Seite 13: Installation

INSTALLATION V-DRIVE gearbox is not flanged directly on to the engine. Make sure that the connecting cardan shaft does not transmit vibration which could damage the transmission. V-DRIVE gearbox is installed separately, with a drive shaft and the foundation mounting can be either rigid or elastic. - Seite 14 GEARBOXES V-DRIVE The advice given in the preceeding paragraph are also valid in this case. If the gearbox is installed sepa- rately, it is necessary to use a universal joint with variable lenght. To make the joint work in the best con- ditions (omokinetic transmission) and to avoid damaging the gearbox or the motor, it is necessary to respect some rules for the installation, as indicated in the following schemes.

-

Seite 15: Maintenance Schedule

An alignment error could cause irreversible damage to the transmission, together with noise, vibration and damage to the hull seal systems. ZF Padova s.r.l. is relieved of all liability for breakage under warranty. When installing the transmission, make sure enough space is left for maintenance access: i.e. changing the oil filter, dipstick access. -

Seite 16: Oil Level Check

OIL LEVEL CHECK The oil level check must be done two minutes after turning off the engine. The correct oil level is between the upper and lower marks on the dipstick (see Fig.17). After the initial filling or after carrying out repairs or changing the oil filter, run the gearbox for about two minu- tes. - Seite 17 SUCTION FILTER CHECK Fig.21 Fig.20 Inspect and clean the suction filter after the first 50 hours of sailing and then repeat every 250 hours and/or 6 months. The filter is located on the inlet side of the oil pump. Removal procedure: take out the plug [1], remove the filter [2], remove the gasket [3] (replacing it with a new one) and clean the filter.

- Seite 18 CHECKING FLEXIBLE COUPLINGS Replace the flexible coupling if, on close inspection, the rubber part has tears or is contaminated with lubri- cating oil. Remove the ignition key before cranking the engine. Do not use chemicals on rubber components. Check that all threaded parts are tight. Lubricate the moving parts of the shift linkage periodically as indicated by the manufacturer.

-

Seite 19: Troubleshooting

- Check operating pressure 6 - Replace oil cooler 1 - Inefficent or erratic oil/water heat 4) Oil level fluctuating exchange 6 You are advised to contact authorised ZF service centres to rectify the points marked with this symbol. EN,IT,FR,ES,DE 3207.758.001 - 2015-06... -

Seite 20: Service Centres

Approximately 400 partners worldwide are dedicated to Sales, Aftersales and Service of ZF marine products. To find your nearest ZF product support, please contact your Regional Competence Center from the list below or visit: www.zf.com and follow: Products & Services/Service network to find a ZF partner in your country. - Seite 21 Phone: +31 183 650 000 info@vanstigt.com NORWAY KGK Norge As TURKEY Caspar Storms vei 19 0664 Oslo ZF Services türk San. Ve tic. A.S. NORWAY ZF Marine Eurasia Phone: +47 22 8846 80 Adil mah. Demokrasi Cad. no:17 firmapost@kgk.no 34935 Sultanbeyli, Istanbul henning.fjeldberg@kgk.no...

- Seite 22 P.R. CHINA Phone: +61 2 9679-5555 Phone: +86 21 2350-0600 info.zf-services.au@zf.com info.zf-services.cn@zf.com www.zf.com/cn ZF Services Australia Pty ltd. (WA) 2 Pavers Circle Holyfort Industrial (HK) Ltd. (China office) Malaga WA 6090 Unit 806, Yu Yi Industrial Bldg. AUSTRALIA Shekou Fishing Port Phone: +61 8 9248-1096 Wanghai Rd., Nanshan Dist.

- Seite 23 Tokyo 105-0021 JAPAN Phone: +81 3 4590-7700 info.tjy@zf.com __________________________________________________________________ AFRICA REGIONAL COMPETENCE CENTER ZF Services South Africa (Pty) ltd. – Cape town branch 29 Proton Crescent Stikland Bellville 7530 SOUTH AFRICA Phone: +27 21 950-9300 info.zfsa@zf.com LOCAL COMPETENCE CENTERS MAROKKO, MAURETANIEN, SENEGAL ALGERIA CAPCI s.a.r.l...

- Seite 24 Copyright © ZF Padova s.r.l. La presente documentación está protegida por los derechos de autor. Sin la autorización de la empresa ZF Friedrichshafen AG, queda prohibida la reproducción y distribución total o parcial de esta documentación. Las infracciones serán perseguidas conforme al derecho penal y civil.

- Seite 25 Anleitungen strikt befolgt werden müssen. ACHTUNG ATENCIÓN Die Firma ZF PADOVA S.r.l. ist nicht haftbar für ZF PADOVA S.r.l. no es responsable de los daños o Schäden oder Verluste infolge fehlerhaftem Einbau, perjuicios de ninguna naturaleza que han sido falschem Gebrauch und unzureichender Wartung causa dos por la instalación errónea, el uso incor-...

-

Seite 26: Kennzeichnung Des Getriebes

Die Anmerkungen enthalten wichtige Informatio- Las notas imparten información importante que es nen, denen besondere Beachtung zu schenken ist. obligatorio leer con atención. ZF 280-1 ZF 280 IV ZF 280-1A Fig. 1 Fig. 2 EN,IT,FR,ES,DE 3207.758.001 - 2015-06... - Seite 27 PRINCIPI DI FUNZIONAMENTO PRINCIPES DE FONCTIONNEMENT Le funzioni principali di un invertitore marino sono le Les principales fonctions d'un inverseur marin sont seguenti: les suivantes: • o accoppiare il motore con l'asse elica e ridurre il • accoupler le moteur avec l'axe de l'hélice et numero di giri dell'elica;...

- Seite 28 L'invertitore consente di ottenere i seguenti tre tipi di L'inverseur permet d'obtenir les trois types de fonction- funzionamento: nement suivants: Folle Point mort L'albero uscita [2] collegato all'asse elica non trasmette L'arbre de sortie [2] qui est raccordé à l'axe de l'hélice nessuna rotazione.

- Seite 29 ZF 280-1 ZF 280-1A Fig. 4 ZF 280 IV Fig. 5 L'invertitore può essere fornito con o senza acces- L'inverseur est fourni avec ou sans accessoires sori (scambiatore di calore, giunto elastico, staffe, (échangeur de chaleur, joint élastique, brides, trol- trolling valve).

- Seite 30 ZF 280 fam. - ZF 280A fam. Fig.6 ZF 280 IV Fig.7 Tab. 1 DESCRIZIONE DESCRIZIONE POS. POS. DESCRIPTION DESCRIPTION POS. POS. REP. REP. DESCRIPCIÓN DESCRIPCIÓN POS. POS. BEZEICHNUNG BEZEICHNUNG Coperchio PTO / Couvercle PTO Scambiatore di calore / Echangeur de cha- Tapa de la TF / Abdeckung Abtrieb leur / Intercambiador de calor/ Ölkühler...

- Seite 31 Prima di mettere in funzione l'invertitore, si deve Avant de mettre l'inverseur en marche, il est eseguire il riempimento e il successivo controllo del livel- nécessaire d'y verser de l'huile et, par la suite, de lo olio. (vedi sez. MANUTENZIONE). contrôler le niveau.

-

Seite 32: Mechanische Trolling Valve (T.v.m.)

TROLLING VALVE MECCANICO (T.V.M.) TROLLING VALVE MECANIQUE (T.V.M.) Il trolling valve è un dispositivo che permette di Le trolling valve est un dispositif qui permet de modifier variare il numero di giri dell'elica indipendentemente le nombre de tours de l'hélice quel que soit le régime de dai regimi di rotazione del motore. -

Seite 33: Elektrische Trolling Valve (T.v.e.)

Cómo se utiliza Bedienung La válvula trolling debe estar desactivada antes de Bevor der Gang eingelegt wird, muss sicherstellt poner la marcha. El operador debe poner primero la werden, dass die T.V.M. ausgeschlossen ist. Nach marcha y después accionar la palanca de la válvula gra- dem Einlegen des Ganges den Schalthebel der dualmente hasta alcanzar la velocidad de maniobra T.V.M. - Seite 34 TELECOMANDI DISTRIBUTORE TELECOMMANDES DU DISTRIBUTEUR Nell’installazione dei telecomandi bisogna Au cours de l'installation des télécommandes, il accertarsi che la corsa della leva, azionata dal est nécessaire de s'assurer que la course du levier, comando in plancia, sia tale da raggiungere i fine actionnée par la commande du tableau de bord, per- corsa.

- Seite 35 [5]. de température de l'huile sur le trou [5]. TIPI DI OLIO TYPES D'HUILE Usare i seguenti oli (vedere normativa ZF-TLM 04 edi- Utiliser les huiles suivantes (voir normative ZF-TLM zione 02/2009): 04 édition 02/2009): Los valores se deben medir utilizando los orificios [5] y Die Werte müssen an den auf der Zeichnung auf...

- Seite 36 Classe dei lubrificanti 04A Oli motore monogrado (API CD/CE/CF-4/CF/CG-4/CH-4/CI-4/SF/SG/SH/SJ/SL o categorie ACEA, A/B/E) Classi di viscosità: SAE 30, in paesi caldi o in presenza di temperature nella coppa dell'olio superiori a +80 °C anche SAE 40 Avvertenza: 1. Sono ammessi tutti i prodotti commerciali a base di olio minerale che soddisfano le specifiche citate.

- Seite 37 Classe dei lubrificanti 04B Olio motore monogrado Classi di viscosità: SAE 30, in paesi caldi o in presenza di temperature nella coppa dell'olio superiori a +80 °C anche SAE 40 Classe des lubrifiants 04B Huile moteur monograde Classes de viscosité: SAE 30, dans les pays chauds ou avec des températures de carter à huile au-des- sus de +80 °C, également SAE 40 Clase de lubricantes 04B Aceites de motor monogrados...

- Seite 38 Denominazione prodotto (04B) Nom du produit (04B) Nombre (04B) Warenzeichen (04B) ADDINOL TURBO DIESEL MD 305 SAE 30 Q8 MOZART DP SAE 30 ADDINOL TURBO DIESEL MD 405 SAE 40 Q8 MOZART DP SAE 40 ANDEROL MYTHOS SAE 30 LIQUI MOLY TOURING HIGH TECH HD 40 ANDEROL MYTHOS SAE 40 TOURING HIGH TECH MOTOROIL SAE 30 TECTROL HDC 30...

- Seite 39 Classe dei lubrificanti 04C Olio motore multigrado Classi di viscosità: SAE 5W-40 / 10W-40 / 15W-40 Classe des lubrifiants 04C Huile moteur multigrade Classes de viscosité: SAE 5W-40 / 10W-40 / 15W-40 Clase de lubricantes 04C Aceites de motor multigrados Clases de viscosidad: SAE 5W-40 / 10W-40 / 15W-40 Schmierstoffklasse 04C Mehrbereichsmotorenöl...

-

Seite 40: Ausfall Der Elektrischen Anlage

DISPOSITIVI DI EMERGENZA / DISPOSITIFS D'URGENCE DISPOSITIVOS DE EMERGENCIA / NOTSCHALTUNGEN AVARIA IMPIANTO ELETTRICO PANNE DE L'INSTALLATION ELECTRIQUE In caso di avaria all'impianto elettrico o ai solenoidi En cas de panne de l'installation électrique ou des delle elettrovalvole è previsto un sistema meccanico solénoïdes des électrovalves, un système mécanique per l'innesto manuale delle frizioni. - Seite 41 INSTALLAZIONE / INSTALLATION INSTALACIÓN / INSTALLATION L'invertitore V-DRIVE non viene flangiato direttamente al L'inverseur V-DRIVE n'est pas bridé directement sur le motore. Verificare che l'albero cardanico di collegamento, moteur. S'assurer que l'arbre de cardan de raccorde- non trasmetta vibrazioni dannose alla trasmissione. ment ne transmet aucune vibration nuisible à...

- Seite 42 X [mm] max. 0,05 Y [mm] max. 0.1 L [mm] min. 500 per d < 60 mm min. 1000 per d 60 ÷ 90 mm min. 2000 per d > 90 mm Fig.14 INVERTITORE V-DRIVE INVERSEURS V-DRIVE Valgono le considerazioni precedenti. Nel caso d'in- Les considérations précédentes restent valables.

- Seite 43 Fig.15 METODO DI ALLINEAMENTO CON ALBERI MÉTHODE D’ALIGNEMENT AVEC ARBRES À CONTROPUNTA CONTRE-POINTE 1 Motore 1 Moteur 2 Invertitore 2 Inverseur 3 Giunto cardanico di lunghezza variabile. 3 Joint de cardan à longueur variable. - Selezionato secondo le istruzioni della casa - Sélectionné...

- Seite 44 à la transmission, du danneggiamento dei sistemi di tenuta dello scafo. bruit, des vibrations, des dommages des systè- ZF Padova S.r.l. viene sollevata, in caso di rotture, da mes d'étanchéité de la coque. qualsiasi prestazione in garanzia. En cas de rupture, ZFPadova S.r.l. est dégagé de tout service sous garantie.

- Seite 45 Tab. 3 Di rollio Longitudinale statico Di beccheggio De roulis Longitudinal statique De tangage Balanceo Longitudinal estático Cabeceo Rollbewegung Längs statisch Stampfbewegung ANGOLI DI INSTALLAZIONE CONSENTITI IN NAVIGAZIONE [°] (Con riferimento agli assi ortogonale e longitudinale dell™albero di entrata rispetto al piano orizzontale) ANGLES D'INSTALLATION CONSENTIS EN NAVIGATION [°] (Avec référence aux axes orthogonal...

- Seite 46 MANUTENZIONE / ENTRETIEN MANTENIMIENTO / WARTUNG PROGRAMMAZIONE DI MANUTENZIONE / PROGRAMME D’ENTRETIEN PROGRAMMA DE MANTENIMIENTO / WARTUNGSZEITPLAIN Tab. 4 INTERVENTI DI MANUTENZIONE OPÉRATIONS D'ENTRETIEN OPERACIONES WARTUNGSARBEITEN Controllo perdite olio Contrôle des fuites d'huile Revisar si hay fugas de aceite Kontrolle der Ölverluste Controllo livello olio Contrôle du niveau d'huile Revisar el nivel de aceite...

- Seite 47 INTERVENTI DI MANUTENZIONE OPÉRATIONS D'ENTRETIEN OPERACIONES WARTUNGSARBEITEN Supporti flessibili Supports flexibles Soportes flexibles Elastische Lagerungen Indicatori e strumenti di controllo Indicateurs et instruments de contrôle Indicadores e instrumentos de control Anzeigen und Kontrollinstrumente Sostituzione anodi in zinco Remplacement des anodes en zinc Sustitución de los ánodos de zinc Zinkanoden auswechseln Scambiatore di calore...

- Seite 48 CONTROLLO LIVELLO OLIO CONTROLE DU NIVEAU D'HUILE Il controllo del livello dell'olio va eseguito dopo due Le contrôle du niveau d'huile doit être exécuté deux minuti dallo spegnimento del motore. Il giusto livello minutes après avoir arrêté le moteur. Le bon niveau olio è...

-

Seite 49: Cambio Olio

CAMBIO OLIO VIDANGE D'HUILE Asportare il tappo [2] di carico ed estrarre l'asta livello Enlever le bouchon [2] de remplissage et ôter la jauge olio [1]. d'huile [1]. Provvedere al drenaggio dell'olio lubrificante rimuovendo Eliminer l'huile de lubrification en enlevant les bouchons i tappi di scarico [3] e recuperare le rispettive guarnizio- de vidange [3] et récupérer les joints. -

Seite 50: Saugfilter Kontrollieren

CONTROLLO FILTRO ASPIRAZIONE CONTROLE DU FILTRE D'ASPIRATION Il filtro in aspirazione deve essere ispezionato e puli- Le filtre d'aspiration doit être contrôlé et nettoyé to dopo le prime 50 ore di navigazione, e in seguito après les 50 premières heures de navigation, puis ogni 250 ore e/o 6 mesi. - Seite 51 REGOLAZIONE TELECOMANDI REGLAGE DES TELECOMMANDES A motore spento togliere la spina di collegamento del Le moteur étant éteint, ôter la fiche de raccordement du cavo telecomando con la leva del distributore. câble de la télécommande avec le levier du distributeur. Collocare la stessa in posizione di marcia avanti.

- Seite 52 INCONVENIENTI E RIMEDI / DETERIORATIONS ET SOLUTIONS PROBLEMAS Y SOLUCIONES / BETRIEBSSTÖRUNGEN UND ABHILFEN GUASTO CAUSA RIMEDIO PANNE CAUSE SOLUTION PROBLEMA CAUSA SOLUCIÓN FEHLER URSACHE ABHILFE 1) Pressione olio assente nel 1 - Assenza d’olio nell’invertitore -Riempire d’olio l’invertitore circuito principale e di 2 - Filtro in aspirazione totalmente intasato *-Rimuovere e pulire il filtro lubrificazione in posizione...

- Seite 53 Ölkreislauf aus dem Kühlsystem * Per porre rimedio ai punti contrassegnati con il suddetto simbolo è consigliabile rivolgersi ai centri autorizzati ZF. * Pour résoudre les problèmes indiqués par ce symbole, il est conseillé de s'adresser aux centres ZF agréés.

- Seite 54 Approximately 400 partners worldwide are dedicated to Sales, Aftersales and Service of ZF marine products. To find your nearest ZF product support, please contact your Regional Competence Center from the list below or visit: www.zf.com and follow: Products & Services/Service network to find a ZF partner in your country.

- Seite 55 Phone: +31 183 650 000 info@vanstigt.com NORWAY KGK Norge As TURKEY Caspar Storms vei 19 0664 Oslo ZF Services türk San. Ve tic. A.S. NORWAY ZF Marine Eurasia Phone: +47 22 8846 80 Adil mah. Demokrasi Cad. no:17 firmapost@kgk.no 34935 Sultanbeyli, Istanbul henning.fjeldberg@kgk.no...

- Seite 56 P.R. CHINA Phone: +61 2 9679-5555 Phone: +86 21 2350-0600 info.zf-services.au@zf.com info.zf-services.cn@zf.com www.zf.com/cn ZF Services Australia Pty ltd. (WA) 2 Pavers Circle Holyfort Industrial (HK) Ltd. (China office) Malaga WA 6090 Unit 806, Yu Yi Industrial Bldg. AUSTRALIA Shekou Fishing Port Phone: +61 8 9248-1096 Wanghai Rd., Nanshan Dist.

- Seite 57 Tokyo 105-0021 JAPAN Phone: +81 3 4590-7700 info.tjy@zf.com __________________________________________________________________ AFRICA REGIONAL COMPETENCE CENTER ZF Services South Africa (Pty) ltd. – Cape town branch 29 Proton Crescent Stikland Bellville 7530 SOUTH AFRICA Phone: +27 21 950-9300 info.zfsa@zf.com LOCAL COMPETENCE CENTERS MAROKKO, MAURETANIEN, SENEGAL ALGERIA CAPCI s.a.r.l...

- Seite 58 ATTESTATI DI MANUTENZIONE / CERTIFICATS D'ENTRETIEN FICHA DE MANTENIMIENTO / WARTUNGSNACHWEISE Ore lavoro / Heures de marche Ore lavoro / Heures de marche Horas de trabajo / Arbeitsstunden Horas de trabajo / Arbeitsstunden Data, timbro, firma / Date, timbre, signature Data, timbro, firma / Date, timbre, signature Fecha, sello, firma / Datum, Stempel, Unterschrift Fecha, sello, firma / Datum, Stempel, Unterschrift...

- Seite 59 ATTESTATI DI MANUTENZIONE / CERTIFICATS D'ENTRETIEN FICHA DE MANTENIMIENTO / WARTUNGSNACHWEISE Ore lavoro / Heures de marche Ore lavoro / Heures de marche Horas de trabajo / Arbeitsstunden Horas de trabajo / Arbeitsstunden Data, timbro, firma / Date, timbre, signature Data, timbro, firma / Date, timbre, signature Fecha, sello, firma / Datum, Stempel, Unterschrift Fecha, sello, firma / Datum, Stempel, Unterschrift...